Automated External Spiral Retaining Ring Installation

Use tapered mandrel to expand ring and install in groove on shaft. (Note: angle of inclination of taper should be 3-5 degrees).

Automated Assembly is used in the manufacturing process as a cost reduction tool that additionally achieves increased production rate and added quality through repeatability.

Feed equipment should be designed to work with rings meeting standard specifications. Most critical is to design equipment that can accommodate the helix and pitch limitations for the type of ring you are using. If the equipment is sensitive to any of these factors, it will require special processing that will add to your costs.

Use tapered mandrel to expand ring and install in groove on shaft. (Note: angle of inclination of taper should be 3-5 degrees).

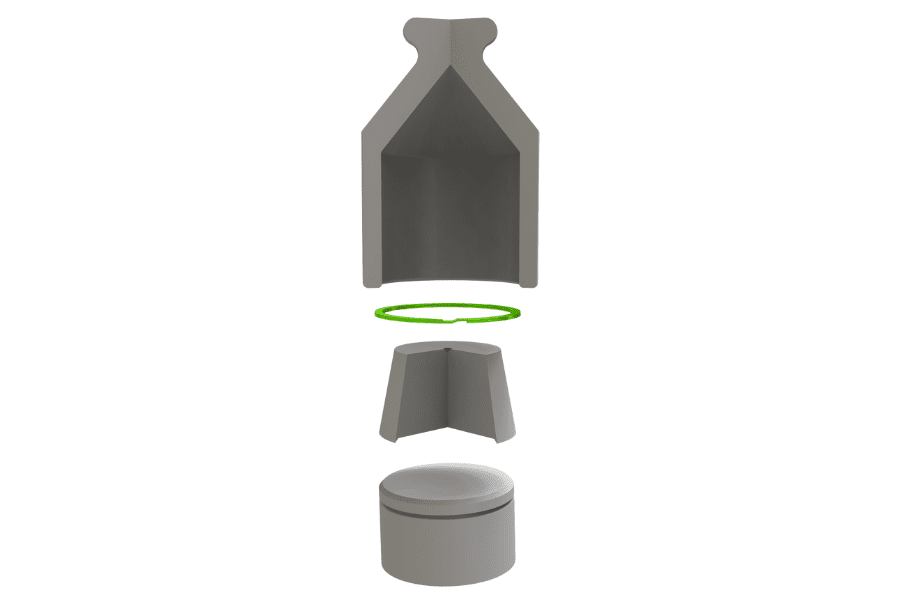

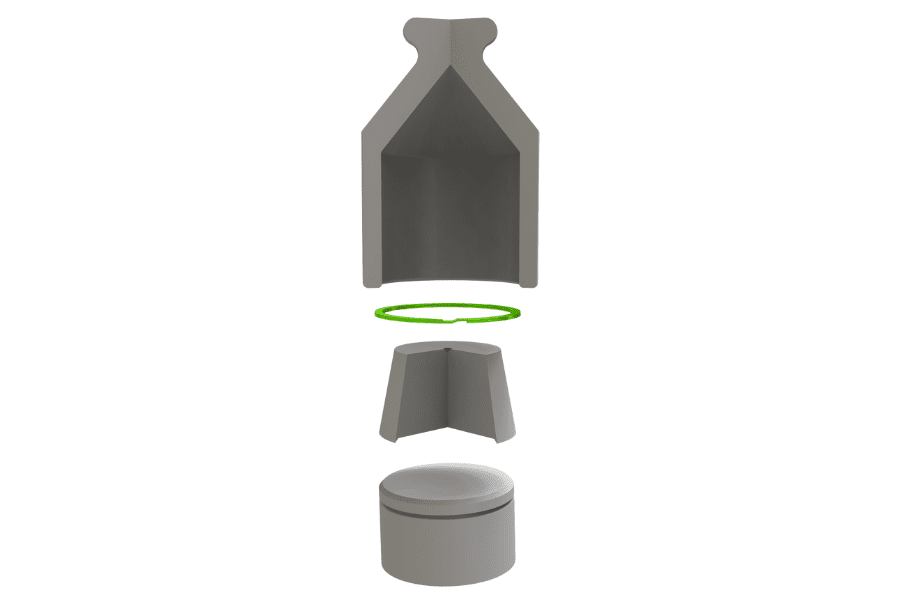

Use tapered housing to compress ring and install in groove in housing. (Note: angle of inclination of taper should be 3-5 degrees).

This is the preferred way to transfer feed an external ring onto a tapered mandrel by using a slide with a complementary cut out for the lugs. (Note: Finger thickness should be 80% of the minimum ring thickness).

This is the preferred way to transfer feed an internal ring into a tapered housing by inserting the mechanism between the lugs (Note: Finger thickness should be 80% of the minimum ring thickness).

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.