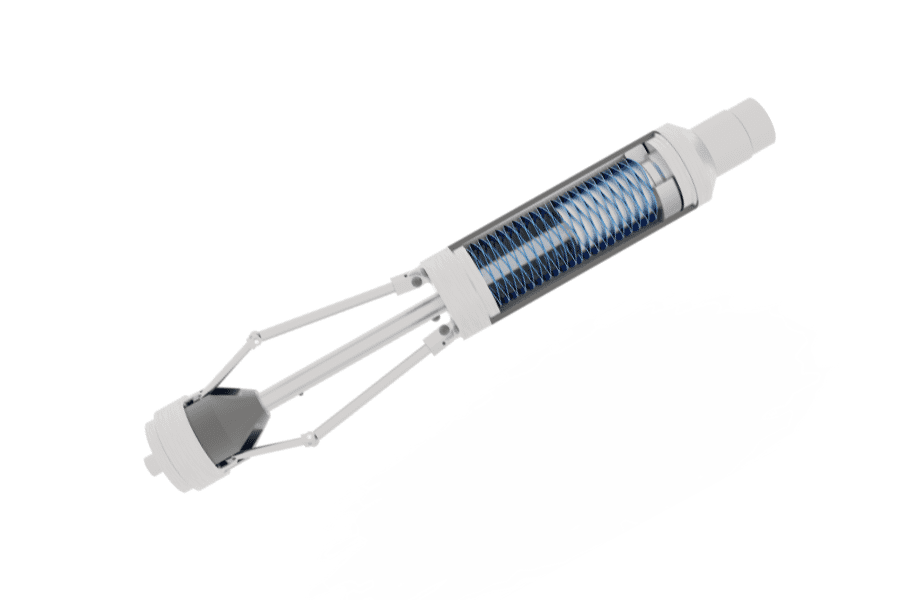

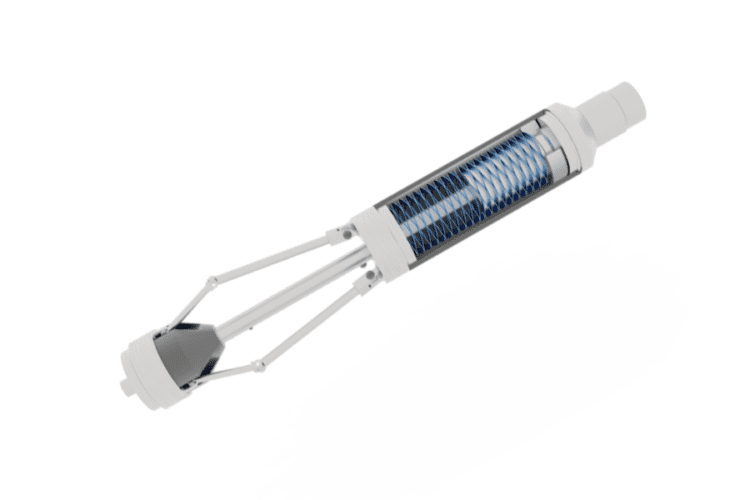

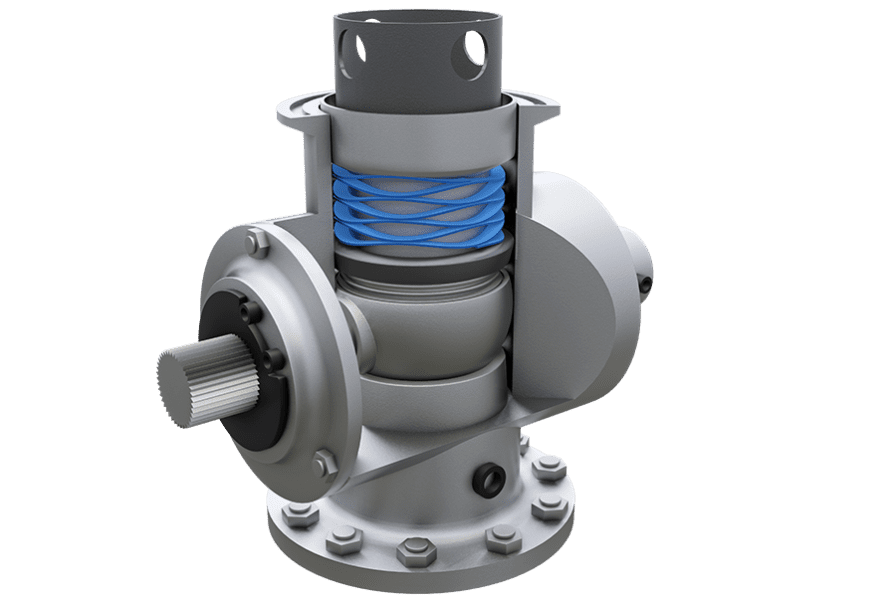

- Pitch systems

- Main shaft bearings

- Yaw systems

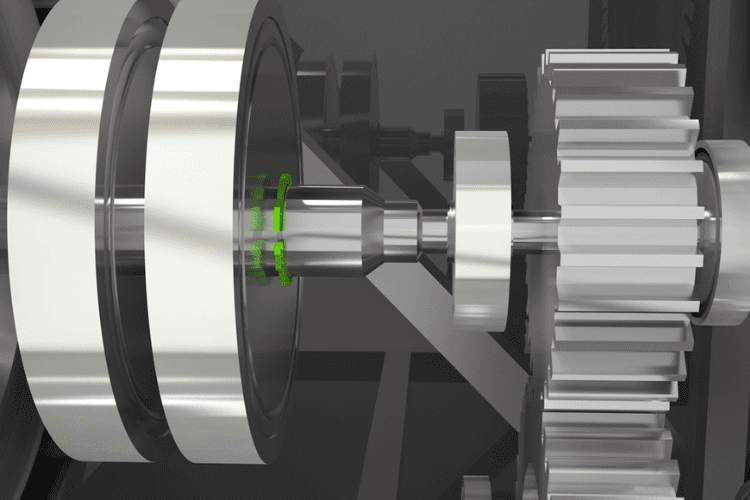

- Gearbox bearings

- Generator bearings

You’re powering the world. You can count on our partnership.

People around the world are counting on oil, gas, and wind to provide power. No matter where you are in the market — upstream or downstream, refining or distributing, under the ocean or in a vast turbine field, you need parts you can rely on.

That’s why the energy industry counts on the dependability of Rotor Clip. Our parts are designed for the high-pressure demands of your field. They are rugged and reliable — just like you. We custom design solutions to ensure full scalability and performance in any condition.

We’re ready to move fast and support you at every step.

All our products are manufactured in accordance with the relevant standards. Our commitment to them is at the heart of our mission. Rotor Clip is certified and registered to ISO 9001, ISO 14001, AS9100, IATF 16949 & ISO 13485

Rotor Clip can manufacture parts in materials required by the industry for high operating temperatures, highly corrosive media and heavy mechanical loads:

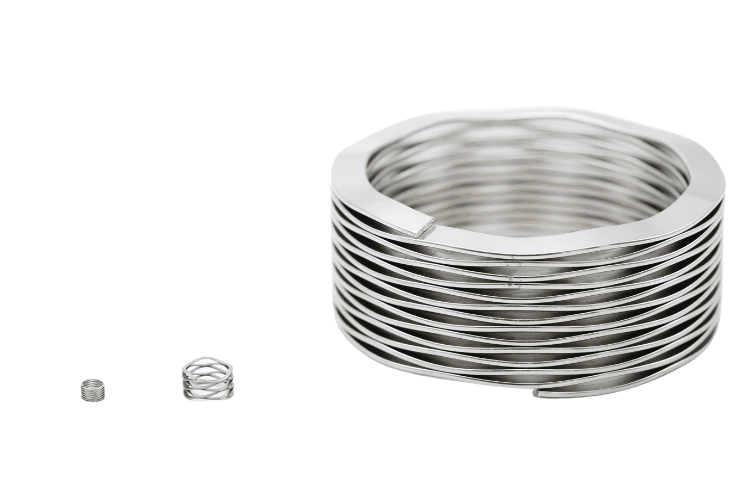

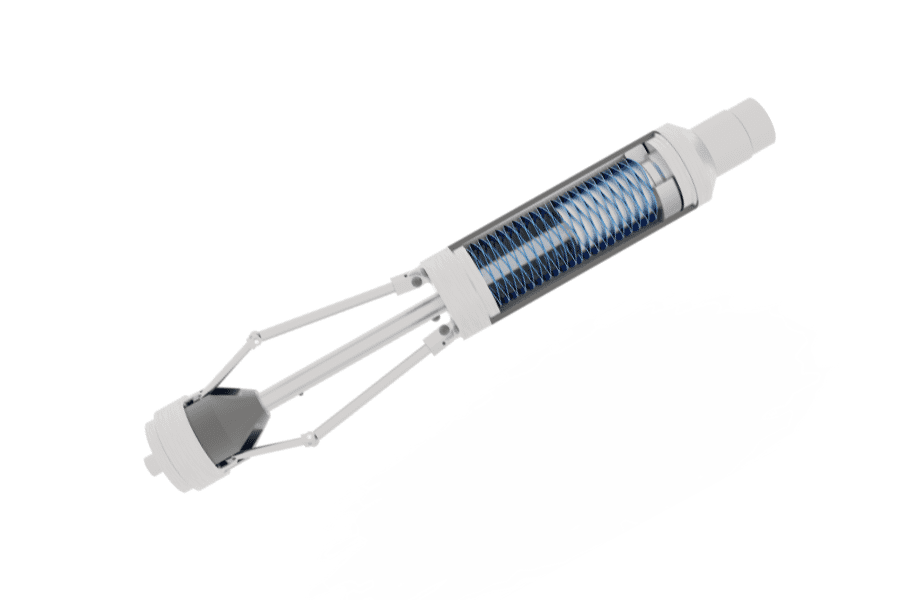

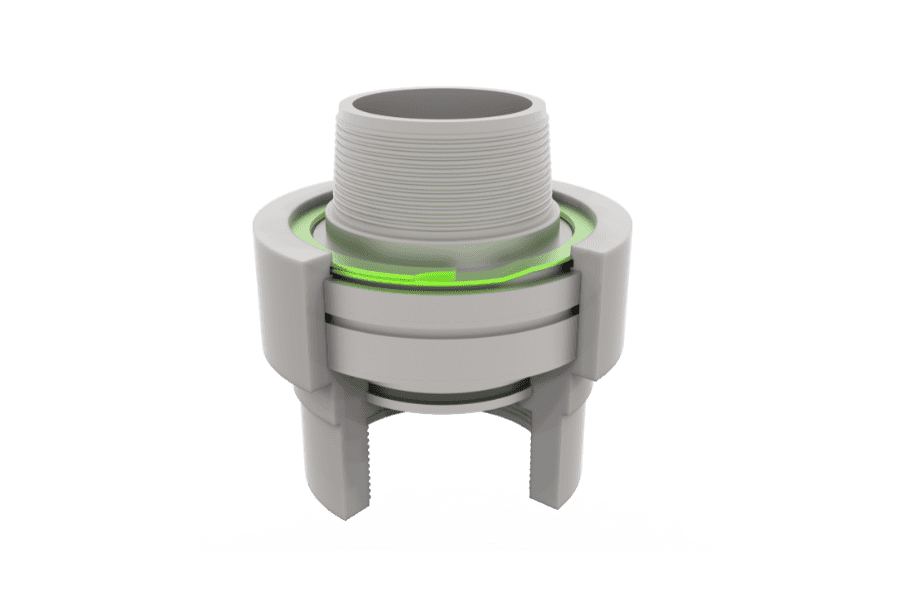

Rotor Clip retaining rings are highly engineered components with tooling designed by our in-house engineering staff and built by our tool room. All processes are performed in-house including forming the rings according to exacting specifications and heat treating them in our own in-house furnaces designed specifically for retaining rings.

The heat treating process is critical since the performance of the ring depends on reaching a pre-determined hardness condition, which is assured through computerized feeding mechanisms and strict quality checking procedures.

Rotor Clip is committed to helping you forge cleaner technologies.

Some projects require retaining rings and wave springs that have been used before. Others are unique and need to be custom made. They all need to withstand the toughest conditions, and help you adjust to changing technologies and an evolving regulatory environment.

That’s why our energy engineer experts can be with you from Day 1. We understand your industry, and have been working alongside you for decades. We understand your requirements and work with you to identify the parts needed for successful builds.

If the solution doesn’t yet exist? We’ll make it. Our one-stop shop allows us to customize, design, and build, with no interference. It’s fast and efficient and we operate at scale.

It’s how we’re more than parts. We’re a true partnership.

No matter where you are in your build, our team can get you the right parts. Our reputation is your assurance.