Wire Coiling

An efficient, in-house coiling process lets us fulfill your order requirements fast!

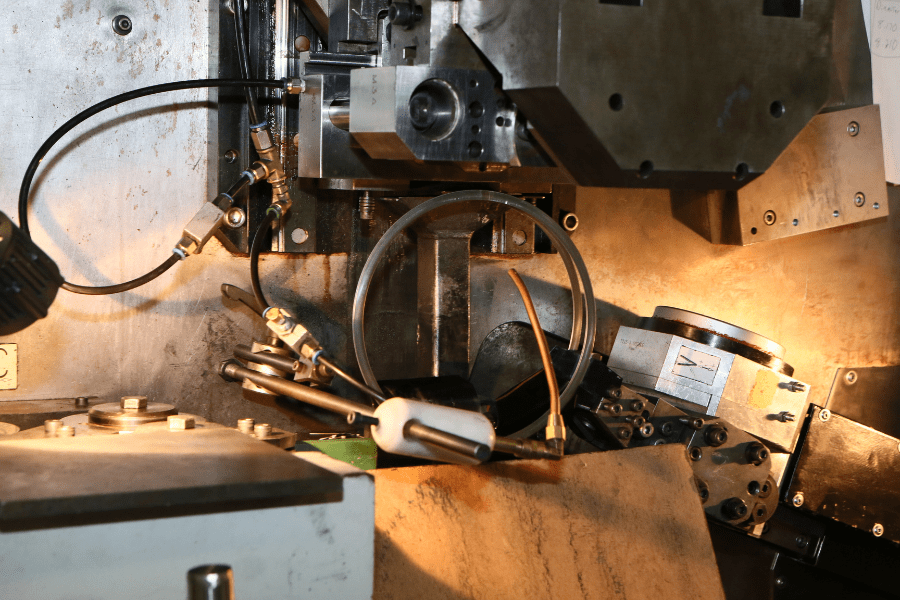

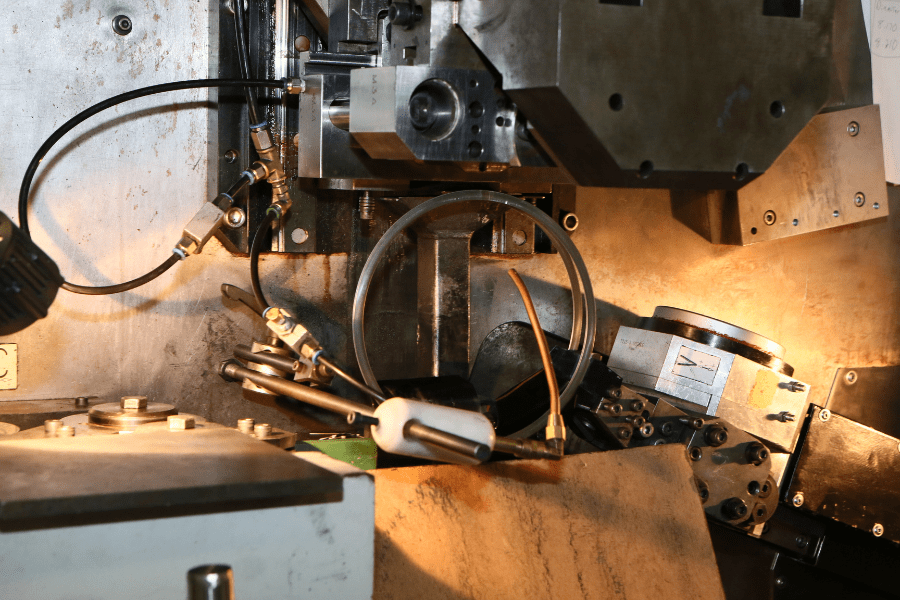

Rotor Clip coils wire parts using a vertically integrated manufacturing environment. We roll our own flat wire, form it in our own machines, and follow it up with immediate heat treatment. At every step of the manufacturing process, from wire coiling all the way through packaging, we efficiently design, create, and deliver your part.

Our wire coiling process is as efficient as it is customizable

For each specific material and size combination, we can configure our wire forming tools to produce a variety of shapes, geometries and profiles without diameter restrictions or additional tooling costs. Changing a design during the manufacturing process requires just simple adjustments to the forming rollers. This flexible, yet inline process makes Rotor Clip ideal for small quantity orders or when you need a prototype fast.

Our wire forming process has additional built-in efficiencies: Wave spring designs, in particular, can be finely adjusted to respond to minor batch-to-batch variations in raw material to maintain targeted performance characteristics. And, we perform frequent manual inspections and keep tight control on all the rolling and coiling processes to ensure high-quality products — every time.

Capabilities

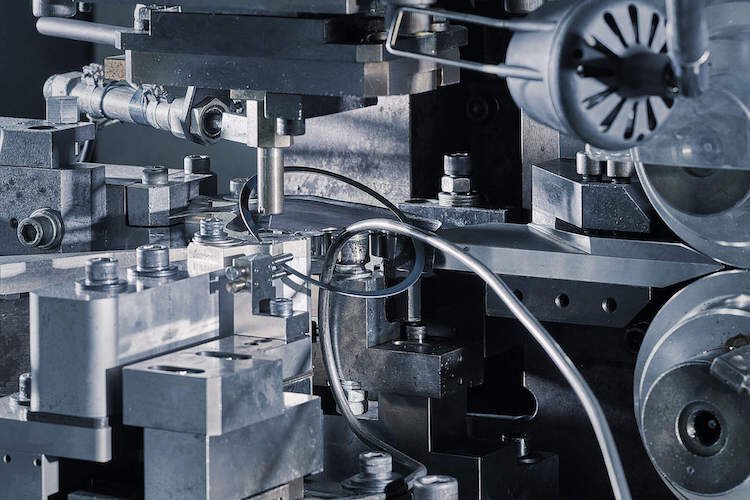

- In-house, automated production yields tight process control and consistent quality.

- Parts are easily configured to a variety of shapes, geometries and profiles.

- Rotor Clip performs tight manual and automated inspection of coiled parts, and statistical analysis of processes.

- Edge coiling from raw materials results in little to no tooling costs.

- Vertically integrated production process. Coiled parts receive immediate thermal treatment and packaging.

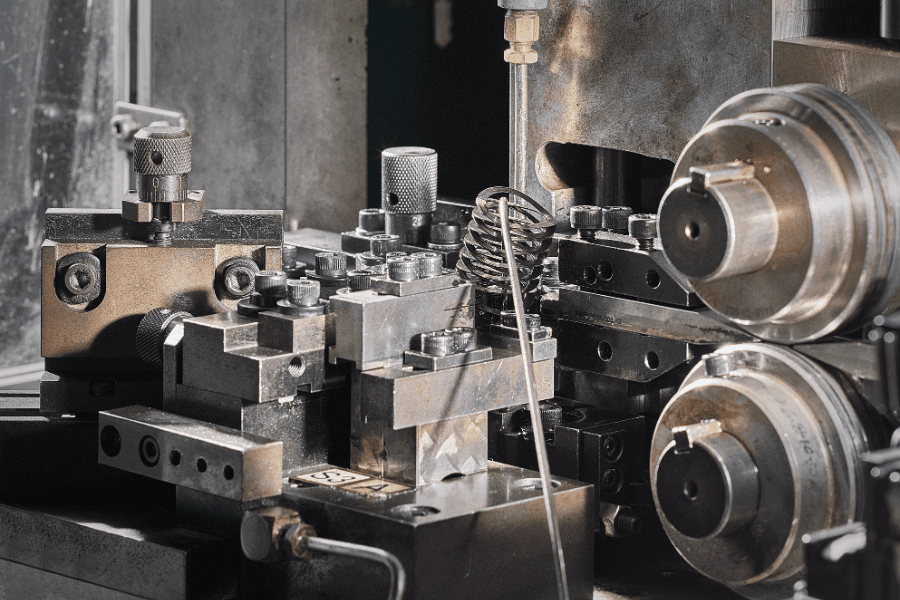

- Rotor Clip produces edge-coiled parts with diameters from 3 millimeters to 600 millimeters.

- Rotor Clip’s edge coiling equipment creates wave springs to a circular shape with one or more turns to specifications in any diameter and any number of specific designed waves.

- Pieces undergo heat treatment directly after coiling to create a streamlined process.

Quality

- An extensive quality policy focuses on meeting and exceeding customer expectations.

- Trained personnel using Rotor Clip’s in-house laboratory facility carefully monitor each step of the manufacturing process. Incoming steel is carefully checked for adherence to chemical composition, dimensional requirements and responsiveness to heat-treating.

- Product provided by Rotor Clip is labelled with a lot number. When needed, this lot number can be used to trace the history of the product, from raw material acquisition to shipment, including inspection records.

- All the rolling and coiling processes are frequently inspected and analyzed to ensure high-quality coiled products.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.