Stamping

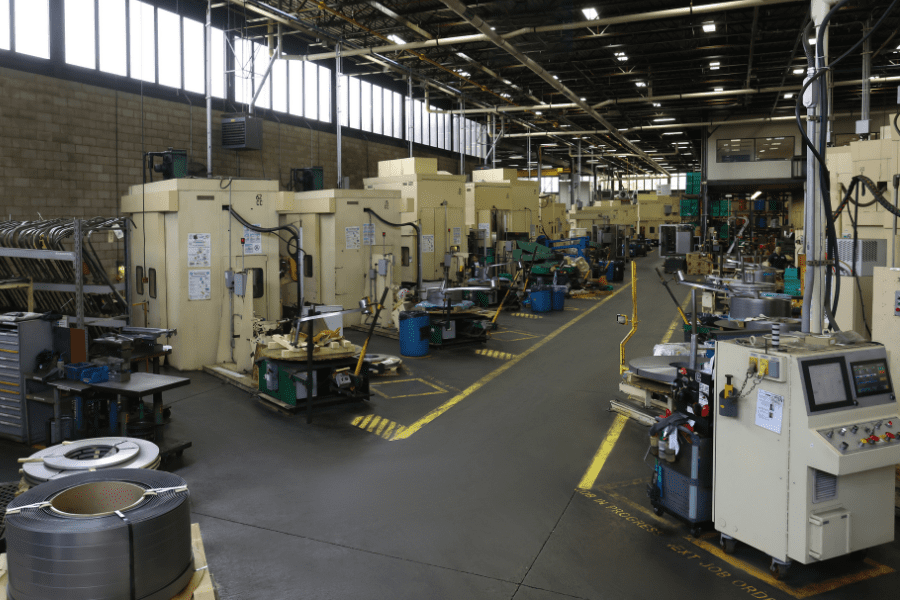

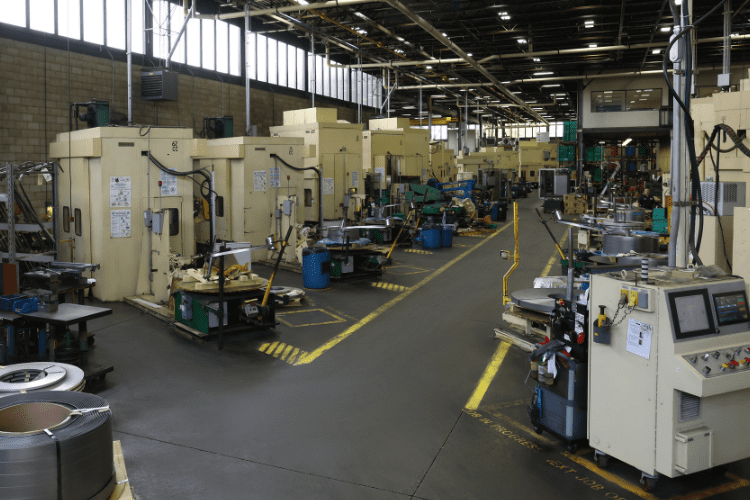

Rotor Clip’s innovative stamping equipment and processes quickly and efficiently deliver consistent, high-quality parts.

Rotor Clip earns its reputation for quality stamped parts every day. Starting with a large roster of modern, premium high-speed and coil-and-cut stamping presses, we exceed our customers’ expectations for quality by continually innovating and improving our equipment and processes to deliver the highest performing part possible.

Rotor Clip devotes extensive resources to enhance the stamping process

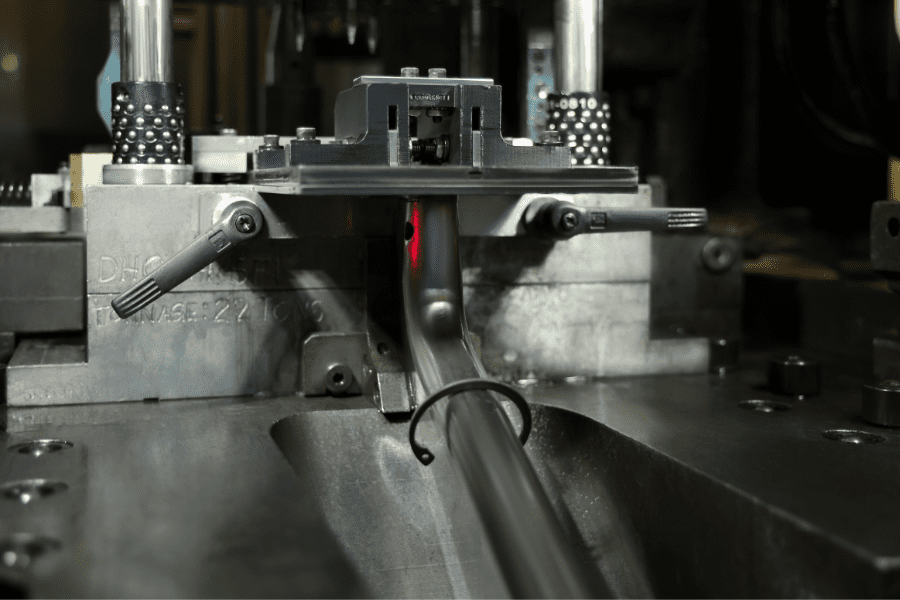

Rotor Clip has a dedicated in-house tool and die facility and a large, expert tooling staff. We design and build many of the modifications that produce stamped retaining rings with high efficiency and accuracy. Whether it’s building a machine accessory to reduce scrap or improve feeding accuracy, or integrating stacking and packaging right onto the presses to suit automated assembly, Rotor Clip devotes extensive resources to enhance the stamping process.

Capabilities

- Rotor Clip maintains a roster of high-speed and coil-and-cut presses.

- Retaining ring bevels and thicknesses are precisely measured.

- An in-house tooling department continually modernizes and upgrades stamping equipment and processes.

- Presses integrate ring stacking and packaging to suit automated assembly and prevent mixed parts.

- Various steel materials are readily available for tight order turnarounds.

- High-speed deburring and polishing are available.

- Rotor Clip houses a fully staffed machine shop inside its 238,000-square foot U.S. manufacturing facility.

- High-speed and coil-and-cut presses have been outfitted with innovative feeding, stacking and packaging attachments.

- A dual-stylus instrument measures contoured parts.

- Rotor Clip’s “Turbo Tumbler” removes unwanted materials after stamping.

Quality

- An extensive quality policy focuses on meeting and exceeding customer expectations.

- Rotor Clip established criteria for determining permanent set limits for basic internal and external retaining rings. We meet accepted industry standards for limitations of dish and pitch.

- Product provided by Rotor Clip is labelled with a lot number. When needed, this lot number can be used to trace the history of the product, from raw material acquisition to shipment, including inspection records.

- Rotor Clip maintains an in-house test laboratory and is capable of checking all phases of mechanical and metallurgical properties involved in the manufacture of retaining rings. Tests include temperature limit and salt spray testing.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.