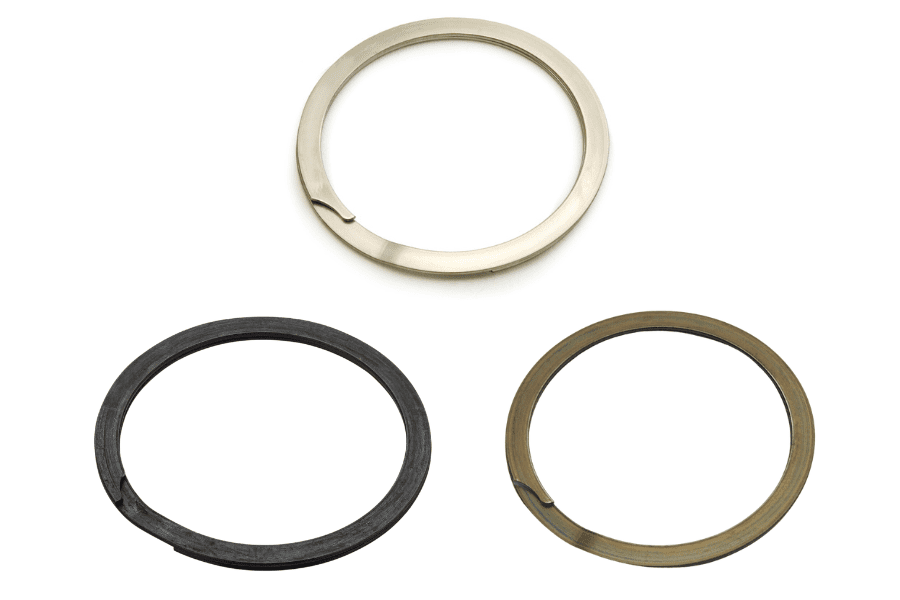

The parts are heat treated for added toughness and may be phosphate coated to protect against corrosion at no additional cost. Customers may select from a wide variety of finishes such as oils, platings, phosphates, zincs and passivation options for further part protection.

And when it comes to ensuring reliability for critical applications like defense and aerospace, you can count on Rotor Clip. Pre-stamped, partially finished parts are readily available for quick coating with military and ASTM-grade finishes. We also stock pre-tested, pre-approved materials — including stainless steels — to respond to aerospace manufacturers’ and contractors’ needs for made-to-order components.