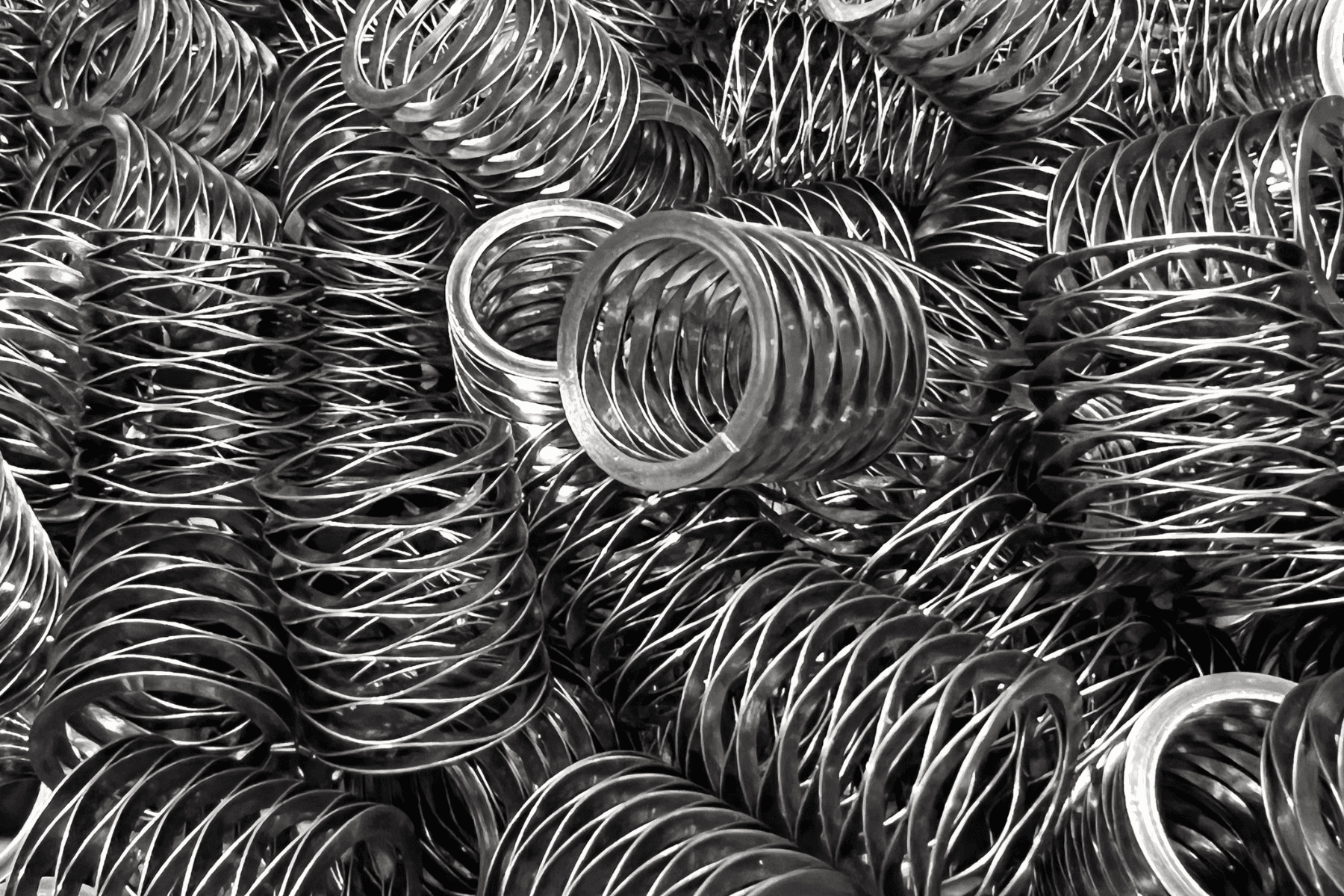

Materials & Finishes for Wave Springs

Materials and finishes to withstand any environment

High-performance materials and finishes to withstand any environment

Rotor Clip offers both standard and special material options for wave springs, with properties such as corrosion resistance, strength, conductivity and heat resistance, to ensure our wave springs withstand even the toughest environments.

To assist customers in selecting the right wave spring for their specific requirements, Rotor Clip’s knowledgeable team of engineers provide guidance and technical support, taking into account factors such as load requirements, environmental conditions and space limitations. By understanding the unique demands of each customer’s applications, Rotor Clip are able to recommend the most suitable material and finishing options to ensure optimal performance and longevity of our parts.

Uncertain about the material or finish required?

Materials Options for Wave Springs

These are commonly used materials for manufacturing wave springs; however, additional options, including titanium and other stainless steel grades, may be available. Please consult our engineering team to explore the best material solution for your application.

Standard Materials

Carbon Spring Steel (Oil Tempered) SAE 1070-1090 (ST)

High-carbon steel alloy, typically tempered with oil, offering excellent strength, resilience, and fatigue resistance. Ideal for springs and high-stress applications requiring durable mechanical properties.

Stainless Steel 17-7 PH/CH900 (SQ)

Precipitation-hardened stainless steel with good strength, corrosion resistance, and heat resistance. It is often used in aerospace, medical, and high-performance applications.

Carbon Spring Steel (Hard Drawn) SAE 1070-1090 (ST)

High-carbon steel alloy drawn to harden it, providing good tensile strength, hardness, and resistance to wear. Commonly used in spring manufacturing and applications with constant loading.

Special Material Grades

Stainless Steel AISI 302 (SJ)

Versatile stainless steel with good corrosion resistance and formability. It is commonly used in fasteners, springs, and applications requiring resistance to oxidation.

Stainless Steel AISI 316 (SU)

Austenitic stainless steel with superior corrosion resistance, particularly in marine and chemical environments. Often used in fasteners exposed to extreme conditions like saltwater.

Inconel X750 (No. 1 Temper, RC 35 MAX) (IN)

A version of Inconel X750 with a controlled hardness (RC 35 MAX) in the No. 1 temper. It provides a balance of strength, toughness, and high-temperature resistance, ideal for gas turbines and industrial applications.

Beryllium Copper (BC)

Copper alloy with a small percentage of beryllium, providing high strength, excellent electrical conductivity, and resistance to wear and fatigue. Used in electrical connectors, switches, and high-performance springs.

Elgiloy (EG)

Cobalt-based super alloy known for its exceptional corrosion resistance, strength, and durability in extreme environments. Often used in the aerospace and chemical processing industries.

Hastelloy C276 (HE)

A nickel-molybdenum-chromium alloy known for its exceptional resistance to a wide range of corrosive environments, including acids, chlorides, and high temperatures. It is widely used in chemical processing, power generation, and pollution control systems due to its ability to resist pitting, stress-corrosion cracking, and oxidation.

A286 Stainless Steel (SY)

High-strength, corrosion-resistant, iron-based super alloy. It offers excellent strength at elevated temperatures, making it suitable for high-temperature applications in aerospace and chemical processing.

Inconel X750 (Spring Temper) (IC)

A nickel-chromium-based super alloy with high oxidation and corrosion resistance. In the spring temper, it offers superior strength and resistance to thermal and mechanical stress at high temperatures.

Inconel X750 (No. 1 Temper) (IC)

A nickel-chromium alloy in the No. 1 temper, offering excellent high-temperature performance, stress-corrosion cracking resistance, and resistance to oxidation and

thermal-fatigue.

Inconel 718 (IN)

High-strength, corrosion-resistant, nickel-chromium alloy designed for extreme environments, especially for aerospace and turbine engine components.

Phosphor Bronze (PB)

This type exhibits higher strength compared to standard phosphor bronze materials with the same tin percentages. It is also characterized by very good stress relaxation characteristics. (Note: Rotor Clip can also supply phosphor bronze material to DIN standard 17 662, Material Number 2.1020. Contact Rotor Clip Technical Sales for more information).

Finishes for Wave Springs

Check out all your options listed below, or reach out for further information.

Oil Dip (OIL)

This standard finish for carbon steel spiral retaining rings offers an extended shelf-life protection against rusting. RoHS & ELV compliant.

Black Oxide (BO)

This flat, black finish is used more for when aesthetics of the part are a factor with minimal corrosion protection. RoHS & ELV compliant.

Electro-polishing

This process removes a thin layer of material from the part resulting in a shiny finish with improved corrosion resistance.

Passivation (SPP)

The passivation process removes “free iron” contamination left behind on the surface of stainless steel due to the manufacturing process. Also, the passivation process facilitates the formation of a thin, transparent oxide film that protects the stainless steel from selective oxidation (corrosion).

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.