In-House Tooling

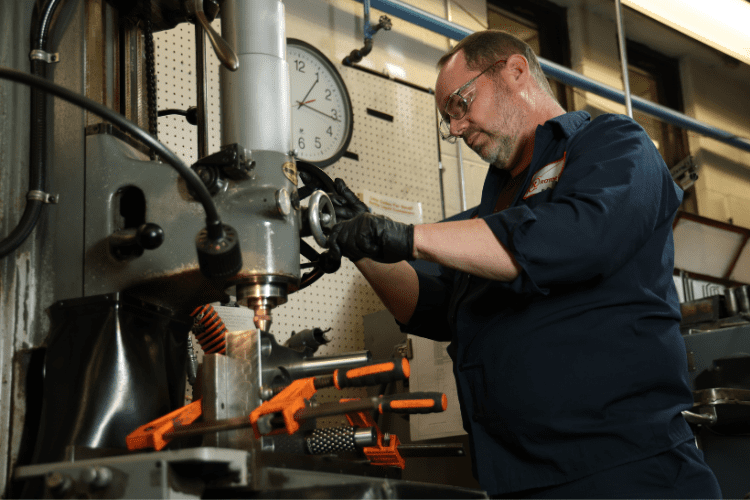

Innovative in-house tooling capabilities and technical expertise drive production quality and timeliness.

Customers can count on Rotor Clip’s adaptive in-house tooling and process design capabilities to satisfy their unique requirements reliably and with the highest quality.

We focus on the most important parameters of the job to better control and place key systems, ensuring a steady flow of product types and sizes while following IATF 16949 guidelines for building and modifying tools. The result is a continuously innovative in-house tooling operation that meets customer demand for highly engineered parts and timely production.

Our skilled staff focuses on the most important parameters of the job to better control and place key systems

Inside our sophisticated tool rooms, Rotor Clip engineers build high-speed, progressive dies using 3D printers and modeling software to solve spatial challenges and CNC machines to generate prototypes and wire electrical discharge machining (EDM). This means we produce parts to tight tolerances with good surface finishes. Not only do we have the equipment and expertise to transform catalog parts into custom parts, we catalog the die inserts, models and tooling as well as carry an abundant stock of high-grade steels and master coils. This vertically integrated operation lets us produce parts and prototypes faster than creating new die, and you can implement them much earlier versus suppliers who outsource their tooling.

Capabilities

- Tooling is performed by an experienced engineering staff at our U.S. and E.U. production facilities.

- Modern CNC equipment controls tool production and laser cutting, and all programming is performed in house.

- Rotor Clip engineers 3D print and model tools, devices and parts to address design challenges.

- Computer-indexed die-changeover inserts, models, techniques and tooling permit seamless custom part production.

- In-house wire EDM equipment produces consistent end products.

- Every tool and die is made to Rotor Clip house standards for repeatable, variation-free results.

- Dies are made for easy and quick servicing.

- Rotor Clip stocks high-grade steel materials, master coils and spare parts to create a tool and make modifications quickly, thereby boosting long production runs and minimizing downtime.

- Tools are produced and laser-cut using modern CNC equipment.

- In-house wire EDM creates parts to tight tolerances with good surface finishes.

- 3D printers, rapid prototyping equipment and modeling software help meet customer requirements for tooling and inspection

Quality

- An extensive quality policy focuses on meeting and exceeding customer expectations.

- All Rotor Clip personnel follow IATF 16949:2016 guidelines for building new tools and repairing existing ones.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.