Qualifying Countries include:

|

|

|

You’re rising to new heights. You can count on our partnership.

Every part, from the biggest to the smallest, has to perform exactly as designed. Our parts are reliable for every mission.

That’s why the defense industry counts on the dependability of Rotor Clip. We’re proud to be the leading global manufacturer of retaining rings, spiral rings, and wave springs for the defense industry. We’ve been there. We’ve worked with engineers like you. Keeping your defense as strong as possible.

Resources

All our products are manufactured in accordance with the relevant standards. Our commitment to them is at the heart of our mission. Rotor Clip is certified and registered to AS9100, ISO 9001, ISO 14001, IATF 16949 & ISO 13485

Rotor Clip offers 100% Military Certified Retaining Rings that are:

DFARS Compliant*

Cage Code: 07382

Made in the USA

At Rotor Clip, there’s no compromise when it comes to getting dependable parts into the hands of people who need them most. Our Aerospace retaining rings and wave rings hold up to our reputation – made with care and trustworthiness.

Rings can be manufactured in sizes from .001″ to 40″ (1mm to 1200mm) meeting inch, DIN, ANSI and JIS standards. Many materials and finishes are available to suit one’s requirements, and Rotor Clip’s knowledgeable sales engineers are available to assist designers in selecting which options are best for their project.

For spiral retaining rings, spring steel (SAE 1070-1090) and AISI 302 stainless steel materials are usually requested for the aerospace industry. 17-7PH Cond. CH900 is the preferred stainless steel for wave springs. Both stainless parts are often passivated to AMS2700.

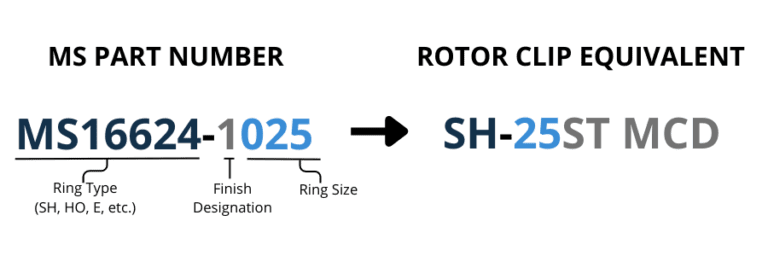

For military applications, cadmium plating of carbon steel is often requested, as well as Black Oxide for camouflage. Rotor Clip offer retaining rings certified to military standards in the popular materials and finishes listed below.

| Material | Finish | MS Code | Rotor Clip Designation |

| Carbon Steel | Cadmium Plated | 1 | ST MCD |

| Carbon Steel | Zinc Dichromate Plated | 2 | ST MZD |

| Carbon Steel | Phosphate Coated | 3 | ST MPD |

| Stainless Steel | Passivated | 4 | SS MPS |

| Beryllium Copper | – | 5 | BC MTM |

Competitor Interchange

Download our interchange tool to convert military parts to the equivalent Rotor Clip part.

Some projects require retaining rings and wave springs that have been used before. Others are unique and need to be custom made. No matter what, you have to make sure you have the right ones in your defense equipment. There’s a lot riding on it.

That’s why our defense engineer experts can be with you from day 1. We help you identify what is needed and find the best solutions to complicated problems.

If the solution doesn’t yet exist? We’ll make it. Our one-stop shop allows us to customize, design, and build, with no interference. It’s how we’re more than parts. We’re a true partnership.

We’re proud to support legislation that provides preferential treatment for domestic sources of un-manufactured articles, manufactured goods, and construction materials. All Rotor Clip products are Defense Federal Acquisition Regulation Supplement (DFARs) compliant*.

No matter where you are in your build, our team can get you the right parts. Our reputation is your assurance.