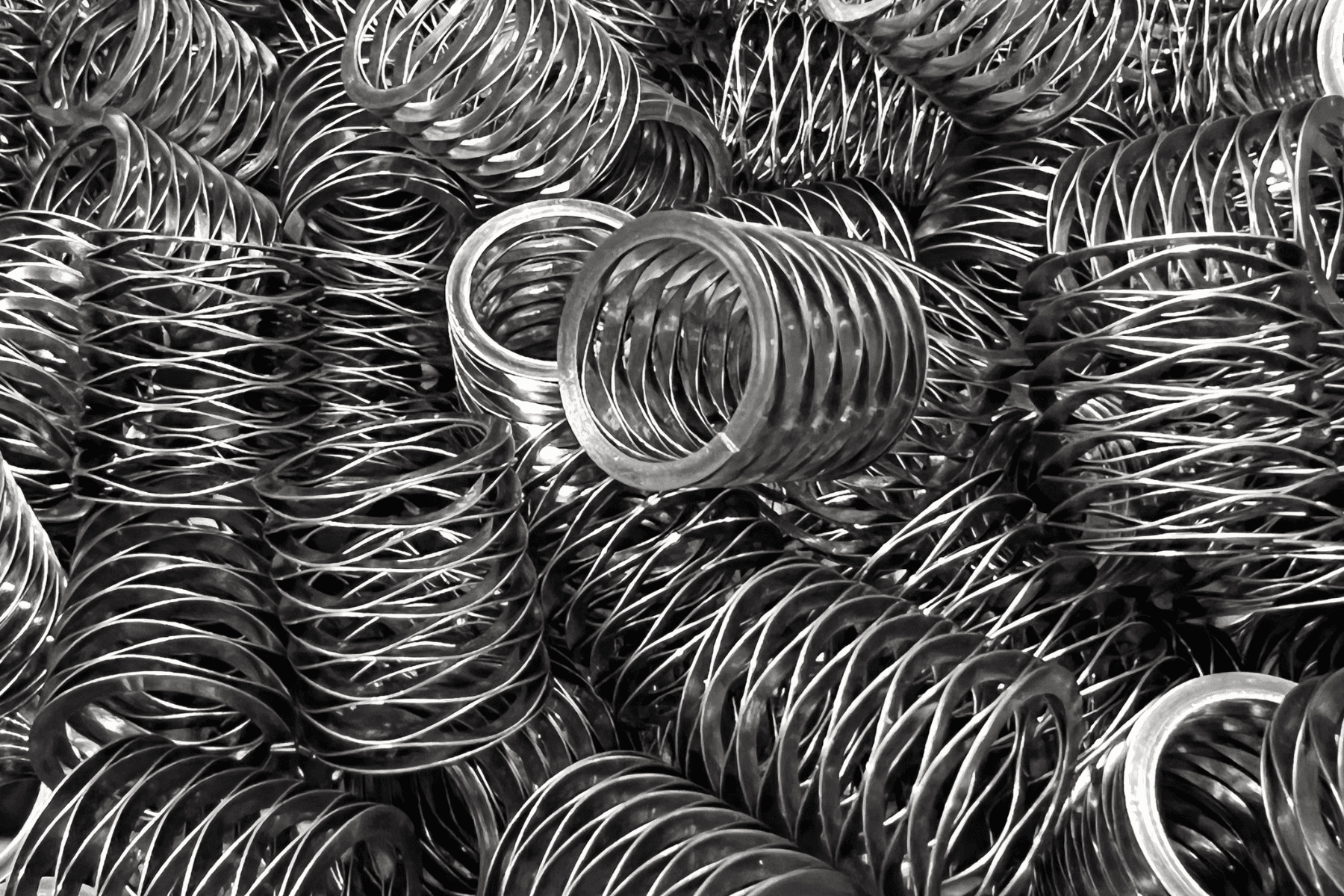

Custom Wave Springs

Every application is unique, that’s why custom wave springs are as common and cost effective as standards. Our engineers have designed springs for the harshest of environments, partner with us and tap into their knowledge.

Providing Application Driven Solutions

Often during the product design process, springs are specified late in the game and unique application requirements dictate the need for customization. As a coiled product, producing a custom spring can be as simple and cost effective as specifying a standard, especially at production volumes.

Customizing parts to suit your needs

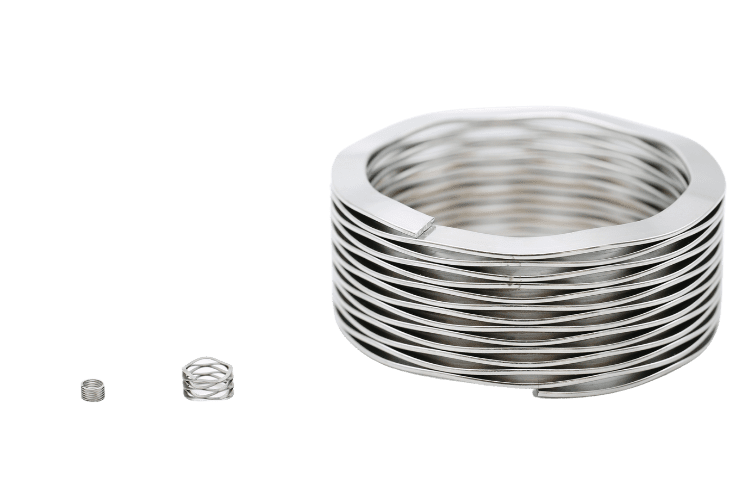

Rotor Clip has the unique ability to design, prototype and scale to your production requirements. To achieve the desired spring forces, rates, and cycle requirements at your specified working height. Almost any property can be modified to achieve your desired results, this includes:

- Outside or inside diameters from .118″ – 24″ (3 mm – 610 mm)

- Material thickness

- Radial wall (material cross-section)

- Number of waves

- Number of turns

- Alloy selection (link to standard, link to exotic)

- End configurations

Materials & Finishes

Our vertically integrated manufacturing process means that our manufacturing capabilities are as diverse as our material offerings. Rotor Clip engineers work with you to determine the best alloy for your application and the environment the spring operates in.

Not only do we offer basic materials like carbon steel and 17-7 PH stainless steel, but can design and manufacture wave springs in:

- AISI 316 Stainless (DIN Material No.: 1.4401)

- A286 (DIN Material No.: 1.4980)

- Inconel X-750 (DIN Material No.: 2.4669)

- Elgiloy (DIN Material No.: 2.4711)

- Hastelloy C276 (DIN Material No.: 2.4819)

- Beryllium-Copper (DIN Material No.: 2.1247)

- Phosphor-Bronze (DIN Material No.: 2.1030)

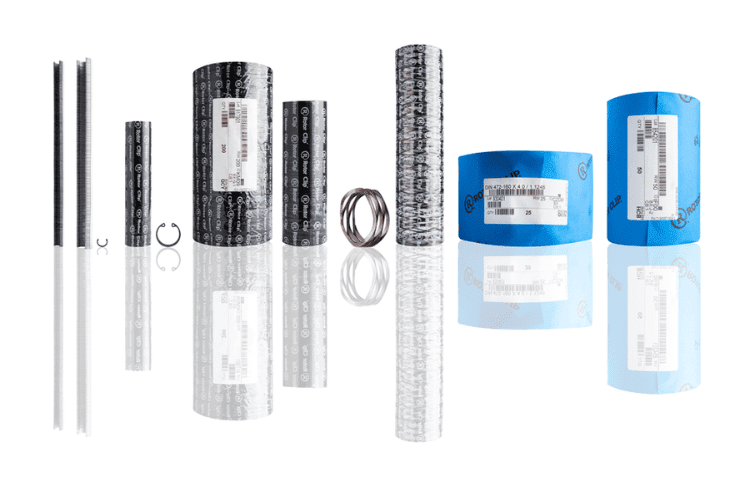

A variety of packaging options to satisfy your installation needs.

Our parts are packaged to satisfy your needs. We have a variety of packaging options available for our retaining rings, but can also work with you to design custom or automated packaging options to optimize your assembly.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.