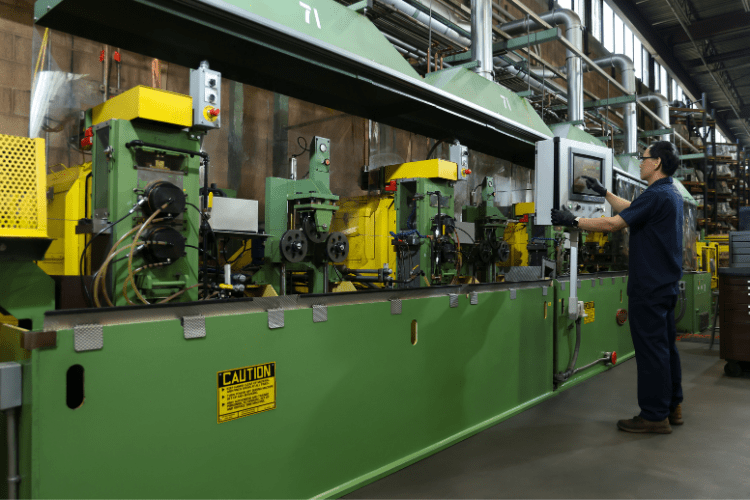

Wire Production

Rotor Clip expertise and in-house wire production help meet your material and quality needs.

When determining the right fastening product for your application, be sure you partner with a company that has significant expertise in producing wire. Rotor Clip shapes and anneals much of its own wire from base stock — including stainless steel wire — yielding more than 4,500 tons of wire from raw materials per year.

Process control from the very first step.

Because Rotor Clip produces so much wire in house, we can continually control and refine our processes to ensure a steady flow of material types and sizes with the mechanical properties customers seek, including hard-to-find, application-specific metals and alloys. This combination of in-house production capabilities, process control and metallurgical expertise lets us react quickly to meet your wire material requirements, perfect your prototype and identify the best opportunities to enhance product quality.

Capabilities

- Rotor Clip produces much of its wire in house, giving us greater process control and material availability so we can provide faster turnaround times.

- In-house wire production, heat treatment, packaging and finishing creates a vertically integrated process that ensures quality and efficiency.

- Rotor Clip can design, prototype and fulfill small-quantity requirements quickly and effectively.

- Coiled flat wire products do not require additional tooling costs.

- Rotor Clip houses a fully staffed machine shop inside its 238,000-square foot U.S. manufacturing facility.

- Our wire forming machinery, engineered to our exacting standards, is efficient, eliminates waste and keeps costs low.

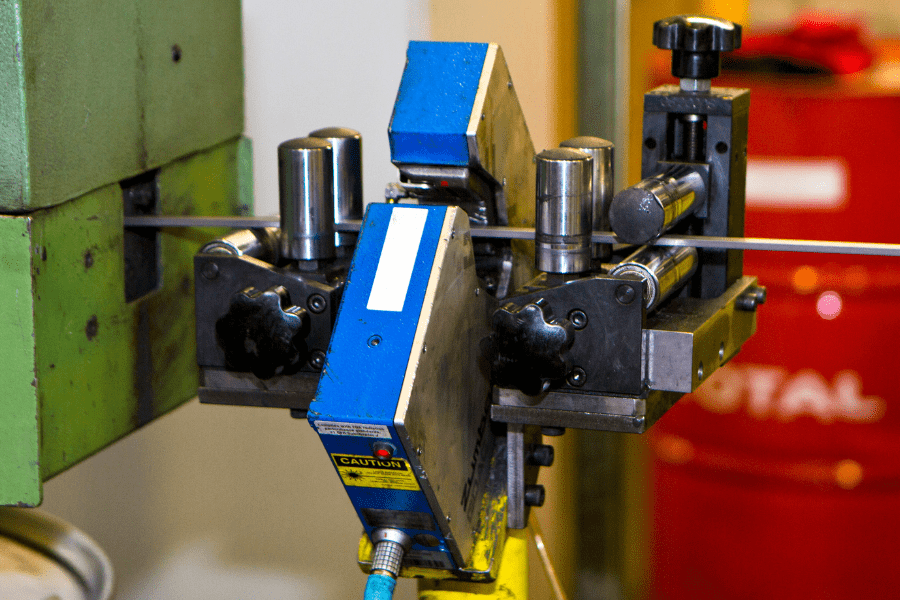

- Laser-based machine vision systems measure and monitor wire production processes.

Quality

- An extensive quality policy focuses on meeting and exceeding customer expectations.

- Rotor Clip maintains an on-site test laboratory. Expert personnel carefully monitor each step of the manufacturing process.

- All incoming steel receives careful multi-point inspection.

- Production lots are traceable from raw material acquisition to shipment, including inspection records.

- Frequent manual inspections keep tight statistical control on all the rolling and coiling processes.

- Rotor Clip uses laser-based machine vision technology to measure wire and detect variations from coil to coil.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.