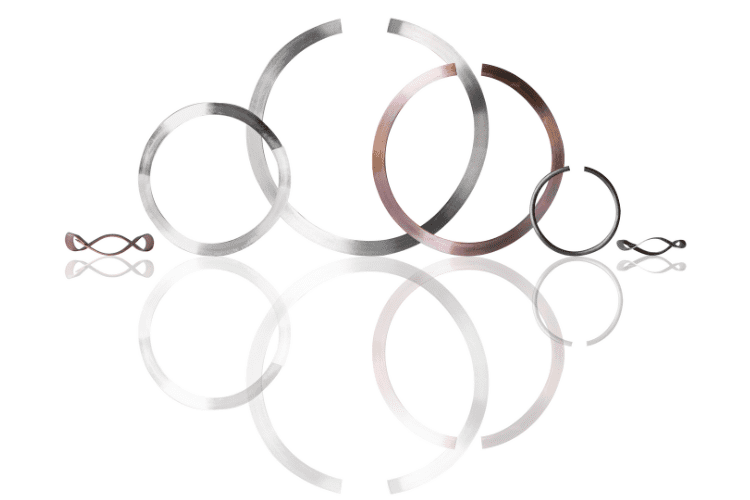

Overlap

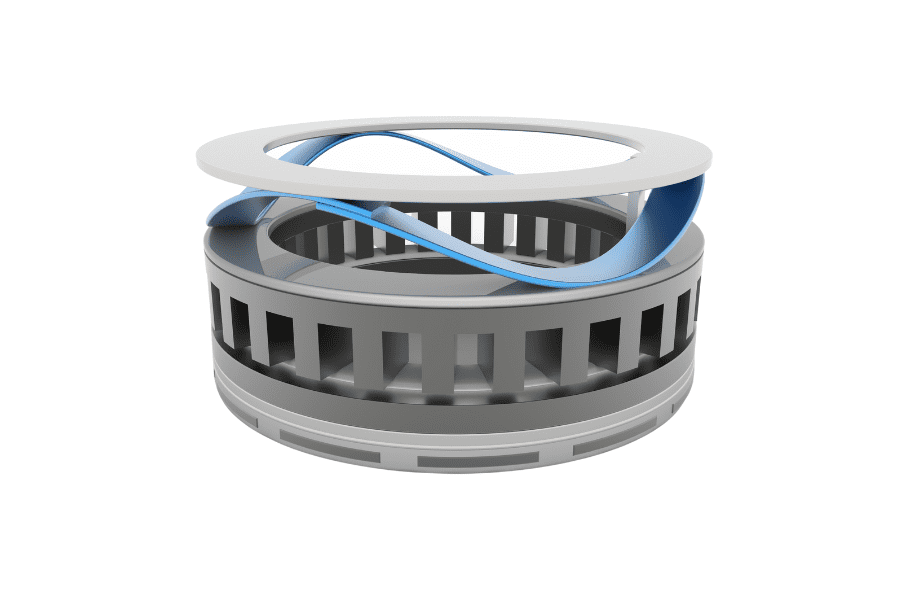

Overlap single-turn wave spring ends come together with one end overlapping the other. The result of this end-type offers no digging while mating with the surface and eliminates parts being tangled in bulk packaging arrangements.

Ideal for short deflection applications with low to medium forces

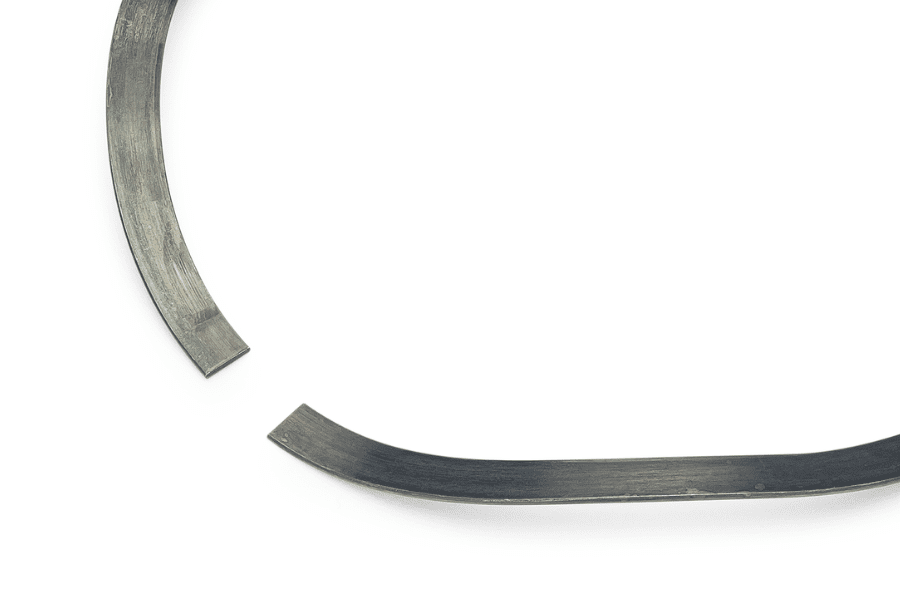

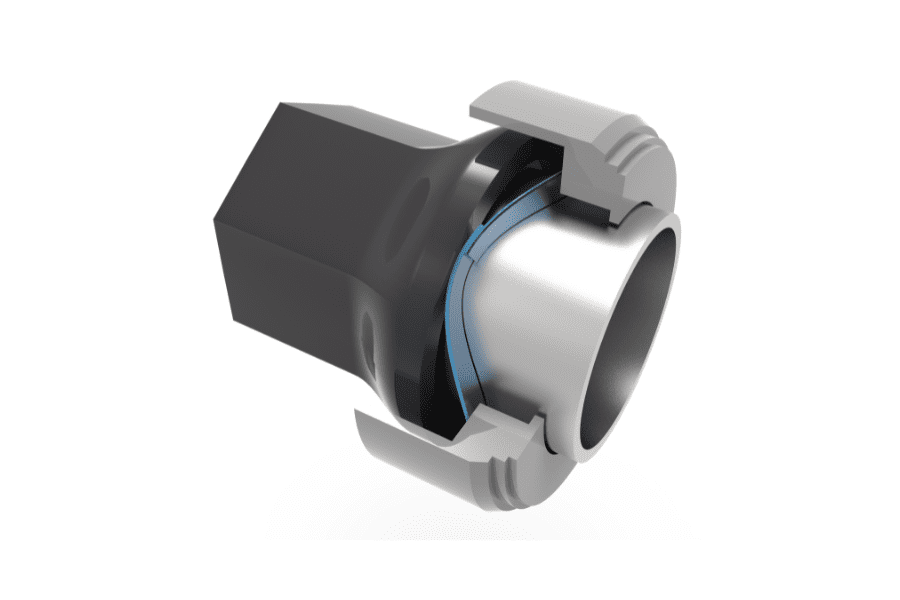

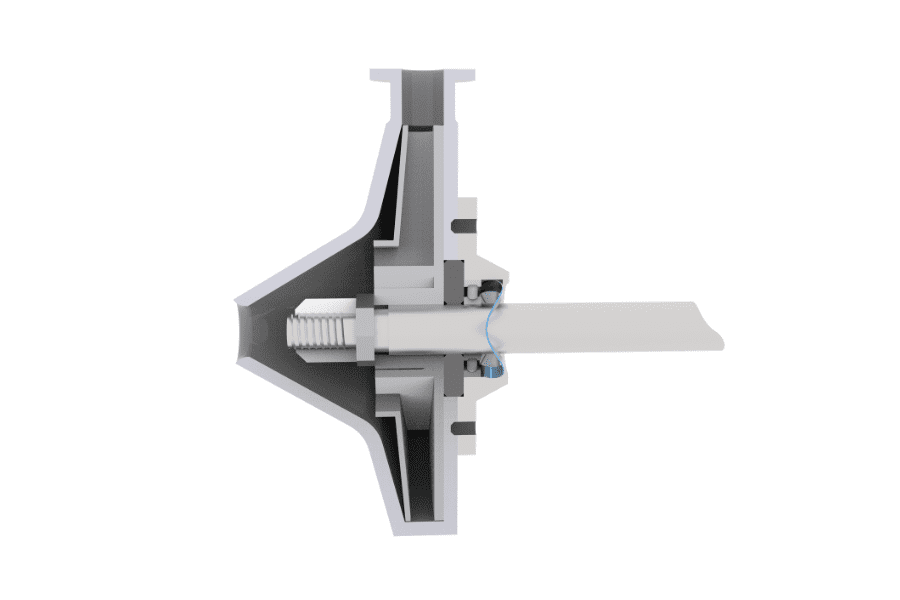

Single-Turn Wave Springs are ideal applications with low to high thrust loads depending on design and wire type. Designed for a range of bore and rod diameters, single-turn wave springs can act as alternative to disc springs and are particularly suited to fit narrow radial wall dimensions and low clearances or to accommodate ball or roller bearings.

Ideal for short deflection applications with low to medium forces. Offered in a number of waves and material thicknesses. Designed for a wide range of bore and rod diameters.

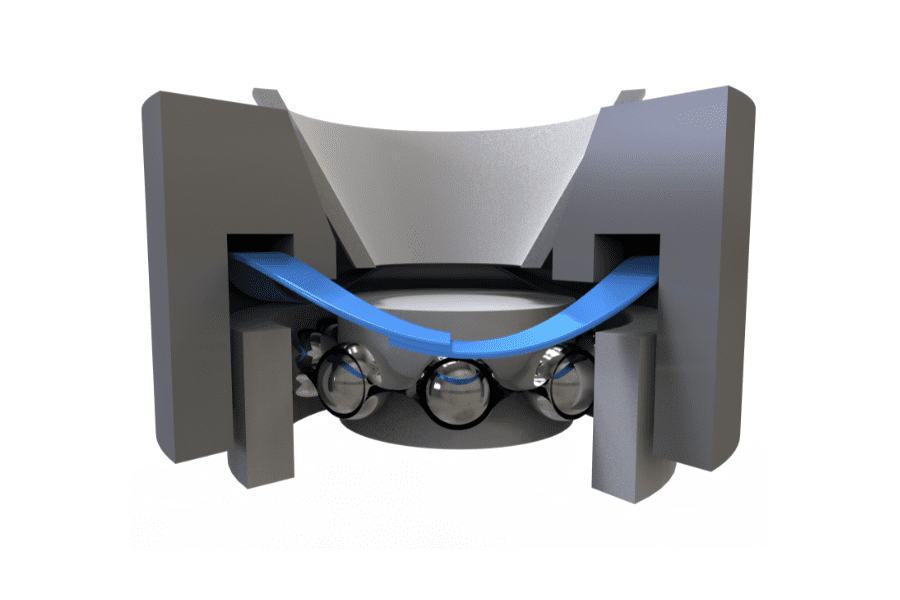

Appropriate where radial space is limited, these wave springs are specified for several standard bearing diameters.

Designed to match popular bearing sizes, it lightly clings in the bore to maximize contact with the outer race of the bearing. Designed to prolong bearing life, reducing vibration and noise.

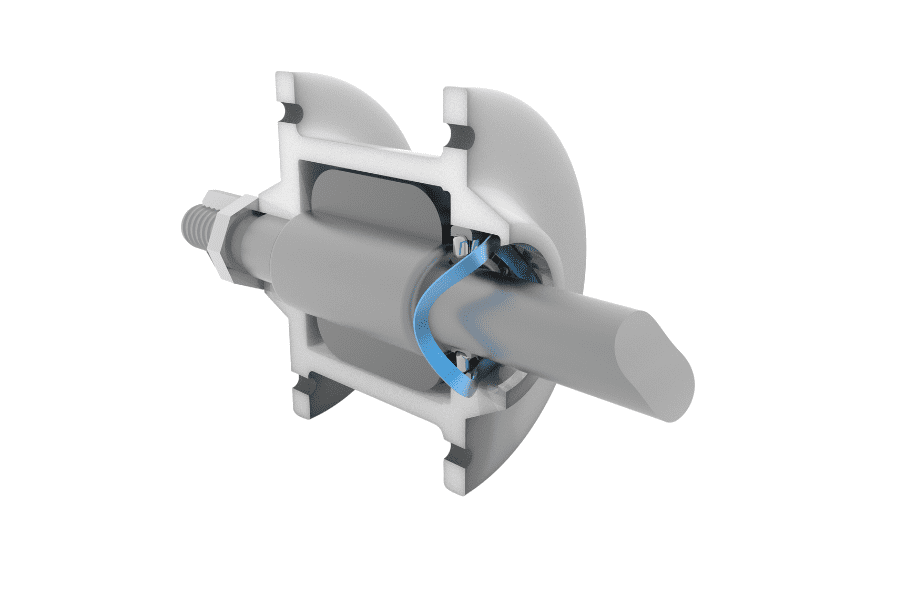

Ideal for use in high load, high rate, low deflection, static, or low cycling applications. Cost effective alternative to disc springs.

Overlap single-turn wave spring ends come together with one end overlapping the other. The result of this end-type offers no digging while mating with the surface and eliminates parts being tangled in bulk packaging arrangements.

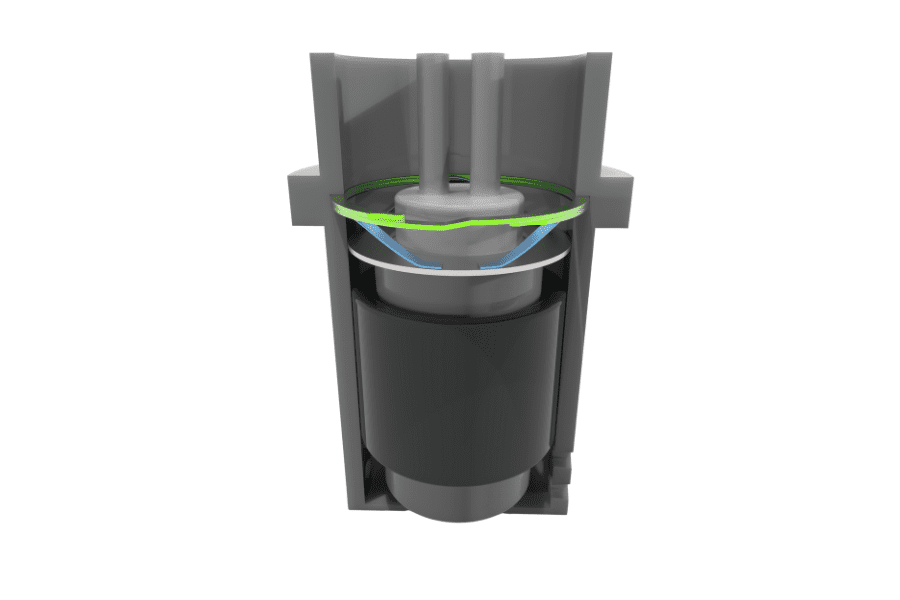

Gap-type wave springs have a physical gap between the ends. Rotor Clip are able to control the distance of the gap, as there may be components that need to clear it.

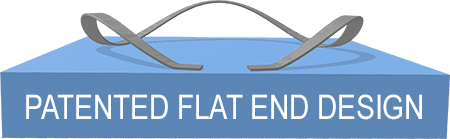

Our patented flat-end wave spring design protects bearings by eliminating sharp, damaging corners from the spring ends, instead flattening them so they rest smoothly against the mating assembly.

Single-turn wave springs can be found in applications across every industry. Here are some examples.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.