With manufacturing, warehousing, and customer service centers strategically located in the United States and Europe, Rotor Clip provides fast access to parts and local support wherever your operations are based. Our in-house engineering and production capabilities, combined with stocked inventories of medical-grade stainless steel and Elgiloy, allow us to respond quickly to design changes, material requirements, and urgent project needs.

ISO 13485 Certified Retaining Rings & Wave Springs for Medical

You’re working to a healthier future. You can count on our partnership.

Precision Rings & Springs Built for Medical Devices and systems

From the smallest wave spring to the largest retaining ring, every part in a medical device must perform exactly as designed. Using the wrong part can compromise patient safety, device reliability, or system performance. Rotor Clip can deliver the parts your application depends on. For over 65 years, we have supplied ISO 13485-certified retaining rings (circlips, snap rings, spiral rings), wave springs, and hose clamps to medical device manufacturers, earning a reputation for precision and reliability in critical applications such as surgical tools, diagnostic equipment, implantable devices, and pharmaceutical systems.

Medical Applications for Rotor Clip Retaining Rings & Wave Springs

From injector pens to hip replacements, oxygen concentrators, and more, Rotor Clip retaining rings, spiral rings, wave springs, and hose clamps provide precise alignment and secure component retention under demanding conditions. Though often hidden within the device, they play a critical role in maintaining assembly integrity and reliability. These parts give medical device manufacturers confidence that their applications function safely and consistently.

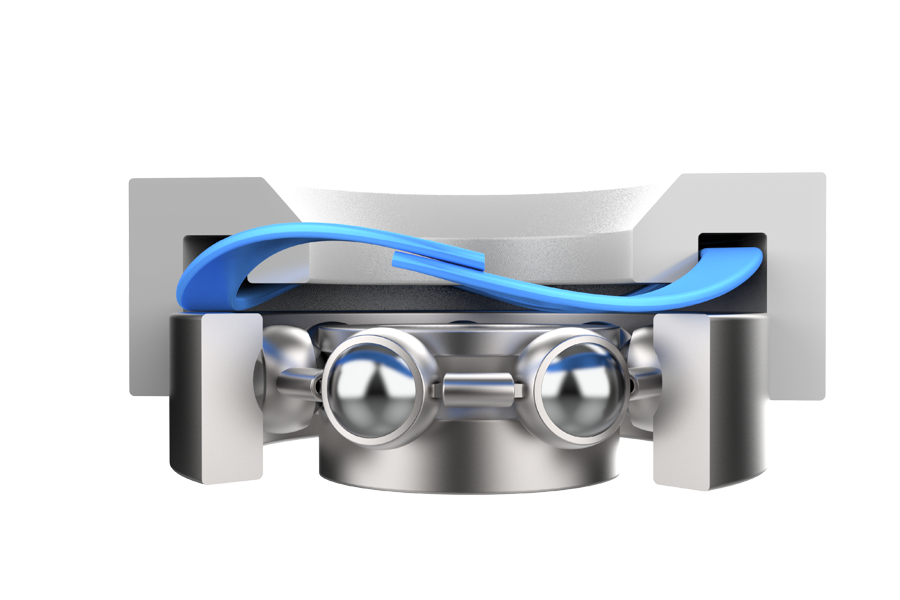

Hip Replacement with Spiral Retaining Ring

Medical Oxygen Concentrator with Multi-Turn Wave Spring

Linear Worm Actuator with Tapered Section Ring (Circlip)

Bearing Preload with Single-Turn Wave Spring

Rigorous Quality Control & Traceability for Every Part

Rotor Clip is ISO 13485 certified for medical manufacturing and also holds ISO 9001, ISO 14001, IATF 16949, and AS9100 certifications. Parts are processed in dedicated cleanroom facilities, with ultrasonic wash systems removing microscopic contaminants to maintain surface quality. Every part is verified by our metallurgical experts using state-of-the-art instruments and in-house labs, ensuring it meets exact specifications. Full product traceability allows each retaining ring, wave spring, and hose clamp to be tracked back to its production lot, materials, and manufacturing process, giving complete accountability and confidence in every part.

Custom Parts Engineered for Medical Devices

Is your application unique and require a solution that a standard part cannot provide? Rotor Clip engineers specialize in designing and producing retaining rings and small diameter wave springs to meet exact specifications.

We manufacture:

- Retaining rings from 0.040″ to 47″ ( 1mm to 1200 mm)

- Wave springs from 0.118″ to 24″ (3 mm to 610 mm)

Typical custom modifications include:

- Number of waves and turns

- End configurations and dimensions

- Material thicknesses

- Tolerances

Medical-Grade Materials, Ready When You Are

Rotor Clip maintains extensive inventories of medical-grade materials in our US and EU warehouses, reducing reliance on third-party suppliers and supporting fast turnaround for standard or custom parts. Our stocked materials allow engineers to source retaining rings, spiral rings, and wave springs quickly, even for urgent or complex applications.

Common materials in medical include:

- 302 Stainless Steel

- 316 Stainless Steel

- PH 15-7 Mo Stainless Steel

- 17-7 Stainless Steel

- Elgiloy

Need a different alloy or finish? Inquire with our engineering team about custom materials now.

Engineering Partnership from Whiteboard to Operating Room

Rotor Clip’s engineering experts work with you from concept to production, helping specify the right retaining rings, spiral rings, wave springs, and hose clamps for your medical devices. We provide in-house prototyping, testing, and material guidance to address complex design challenges and accelerate development. Early collaboration lets us support custom modifications, optimize performance, and reduce project risk. With local expertise and global reach, Rotor Clip delivers engineering support wherever your medical device project takes you.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.