Assurance of Exactness

When you need a custom part, we don’t have to go looking for one that fits. We build to your exact specifications.

Every application is unique, that’s why we engineer the part you need, in the size and alloy you require

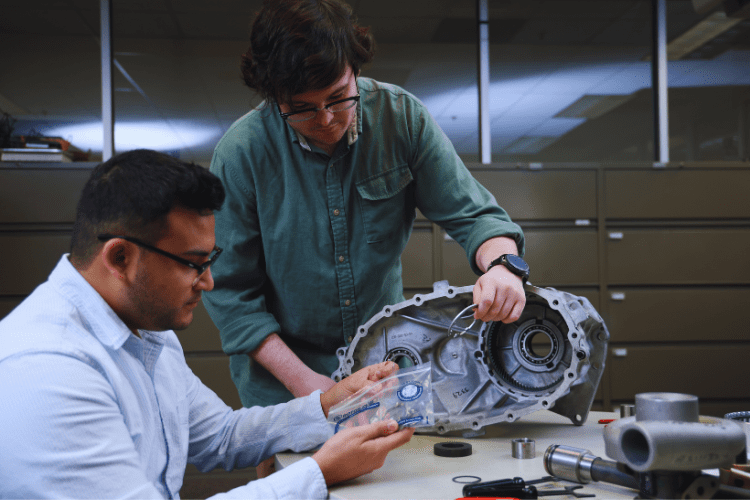

When you need quality products to suit your application, count on Rotor Clip’s expertise to produce any part to your exact needs. Whether you have a requirement that can’t be satisfied by an existing product or if you need a modified version of one of our standard products, you’ll receive a custom part with the same quality and level of service that you’ve come to expect from Rotor Clip. Our design engineers are available for consultations to ensure you receive the best solution from prototype to production.

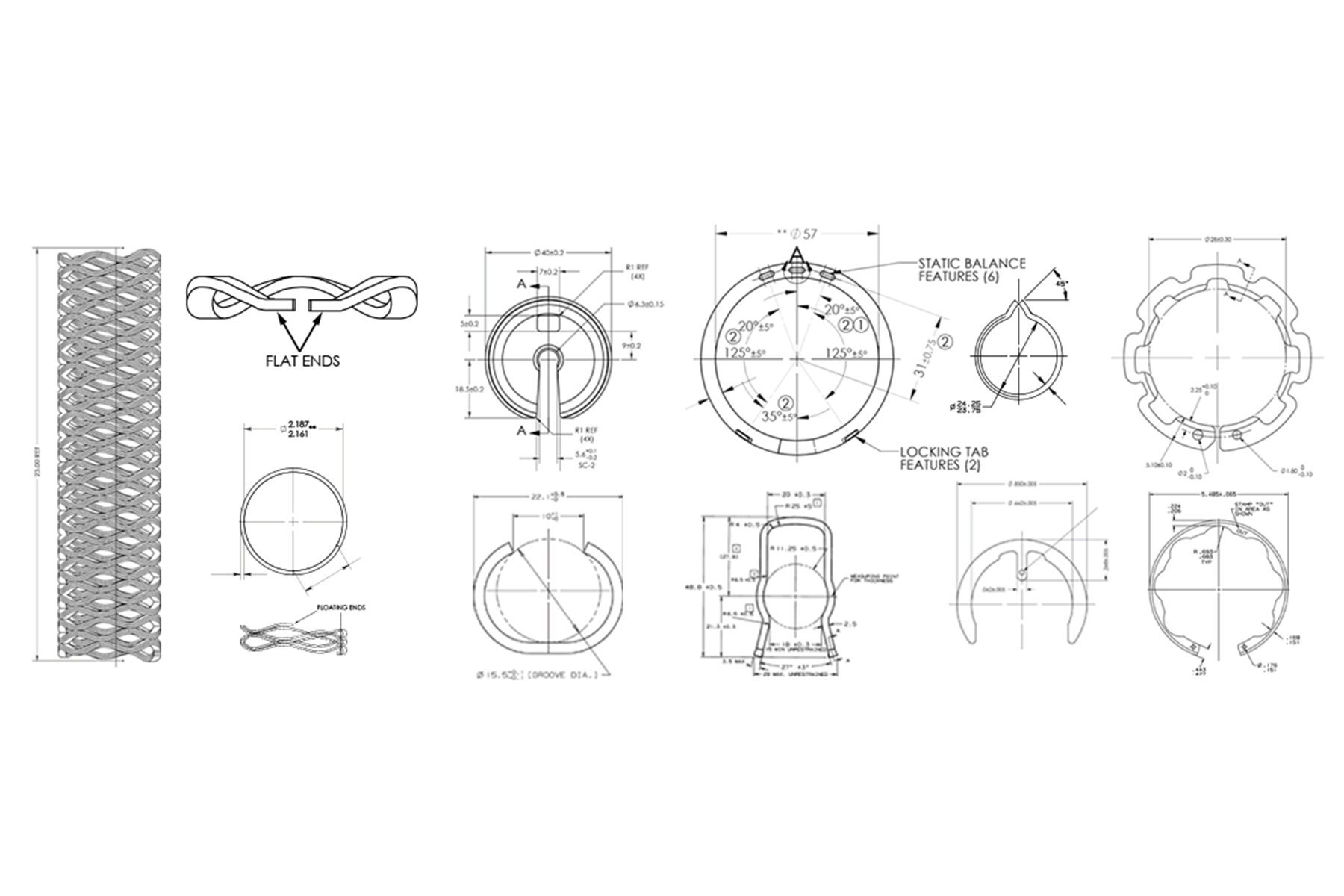

Our experienced engineers will work with you from start to finish to design and produce tapered, constant section and spiral retaining rings along with wave springs to your desired specifications. Typical modifications include thickness, diameter or alternative materials.

Rotor Clip’s versatile manufacturing process and extensive experience serving nearly every industry make us the ideal partner when specifying a ring or spring for your applications. Our engineers have designed tens of thousands of retaining rings, wave springs and hose clamps, we have produced billions of parts and there’s nearly endless combinations of part characteristics that can be modified to ensure the best fit.

Why do we do it the old-fashioned way? Because it works for you.

When you need a custom part, we don’t have to go looking for one that fits. We build to your exact specifications.

In many cases, our engineering teams help design your custom parts, and the knowledge transfer to manufacturing is seamless.

Our 100% in-house manufacturing philosophy eliminates any risk of delay due to incoming goods from overseas. We build. We ship. We get there on time.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.