Finishing Operations

Rotor Clip’s standard and specialty finishing operations will safeguard your investment.

Rotor Clip makes sure your metal products will perform in their intended environments. Our carbon steel retaining rings come standard with a phosphate coating, and carbon steel spiral rings receive an oil dip to protect against rust. Because some applications can present long-term exposure to corrosive conditions, Rotor Clip coating and plating options can resist salt spray for up to 72, 96 or 240 hours depending on the coat selected and operating conditions.

Exceptional finishing options that elevate the performance and longevity of your assemblies.

Rotor Clip offers a wide range of exceptional finishing options for our retaining rings, wave springs and hose clamps, ensuring that our products meet the highest standards of quality and performance. From various plating and coating options to achieve enhanced corrosion resistance, such as zinc, phosphate, and passivation, to specialized treatments like black oxide and oil coating for improved lubrication, we provide the flexibility to tailor the finish to your specific application needs. Our meticulous attention to detail in the finishing process ensures that our parts not only deliver reliable functionality but also exhibit superior durability in challenging environments.

Capabilities

- Specially built heat-treatment furnaces and quench tanks transform parts to their desired hardness.

- In-house heat treatment and tight controls produce parts to an optimal hardness.

- Stamped and stacked Rings on Wire transfer in-line from furnaces to phosphate coating equipment.

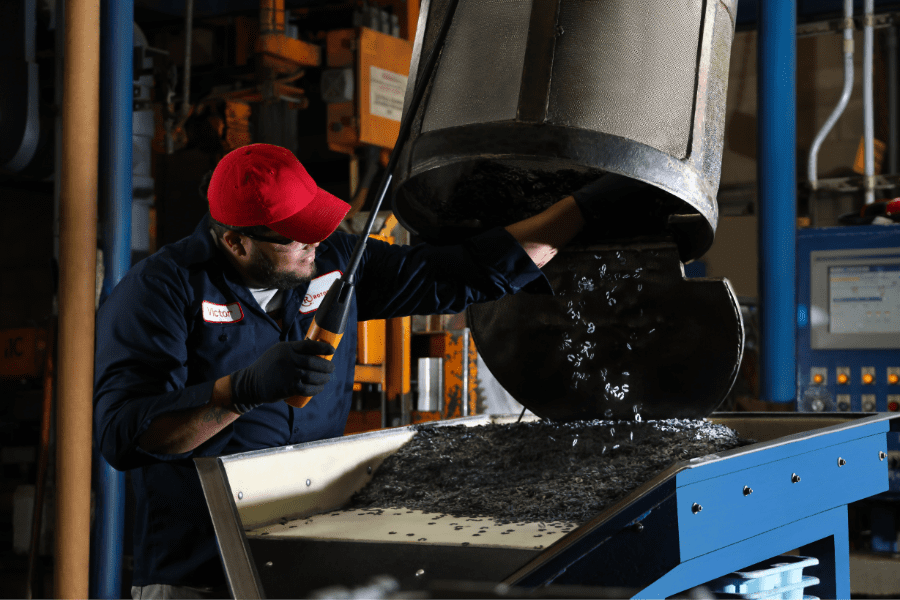

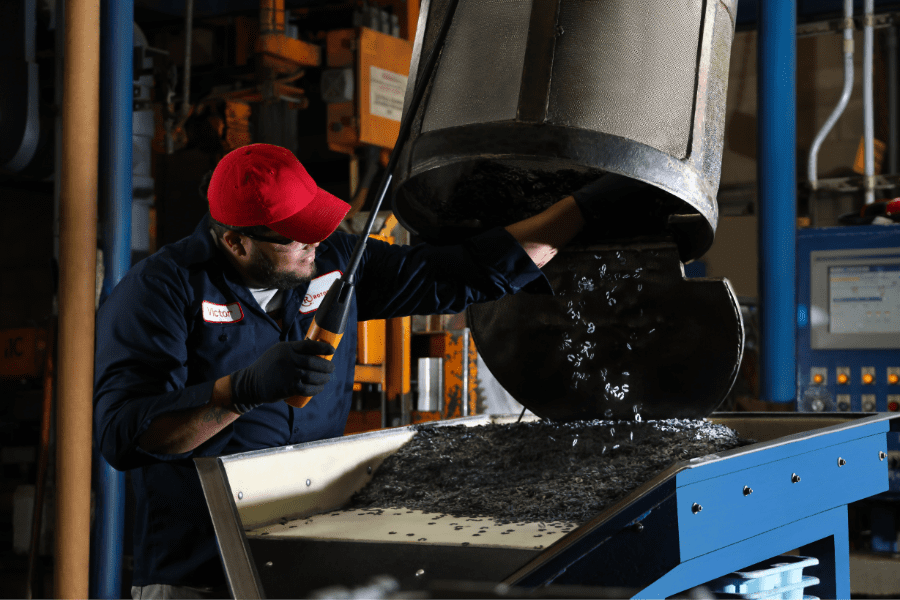

- Tumbling can be performed to specific customer requirements.

- Rotor Clip’s “Turbo-Tumbler” high-speed centrifugal machine deburrs retaining rings in minutes.

- High-speed deburring can remove unwanted materials caused by stamping when requested.

- Salt spray protection can reach 240 hours.

- Test chambers titrate and check samples to ensure coatings withstand salt spray exposure.

- Stainless steel parts are passivated quickly after production to prevent corrosion.

- Mechanical zinc plating equipment effectively avoids embrittlement.

- Passivation baths and rinses remove free irons and prevent corrosion on 15-7 stainless steel parts.

- Rotor Clip finishes and coatings are applied reliably and perform consistently.

- A wide selection of oils, platings, phosphates and zinc options are also available for specialized protection.

Quality

- An extensive quality policy focuses on meeting and exceeding customer expectations.

- Rotor Clip maintains an in-house test laboratory and is capable of checking all phases of mechanical and metallurgical properties involved in the manufacture of retaining rings. Tests include temperature limit and salt spray testing.

- Rotor Clip can supply certain retaining rings and spiral rings with coatings, platings and finishes that meet stringent and demanding military and aerospace application requirements and perform documentation.

- AIAG Assessment compliance. Rotor Clip satisfies the following Automotive Industry Action Group Assessments annually:

- AIAG CQI-9 Heat Treatment Assessment

- AIAG CQI-11 Plating System Assessment

- AIAG CQI-12 Coating System Assessment

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.