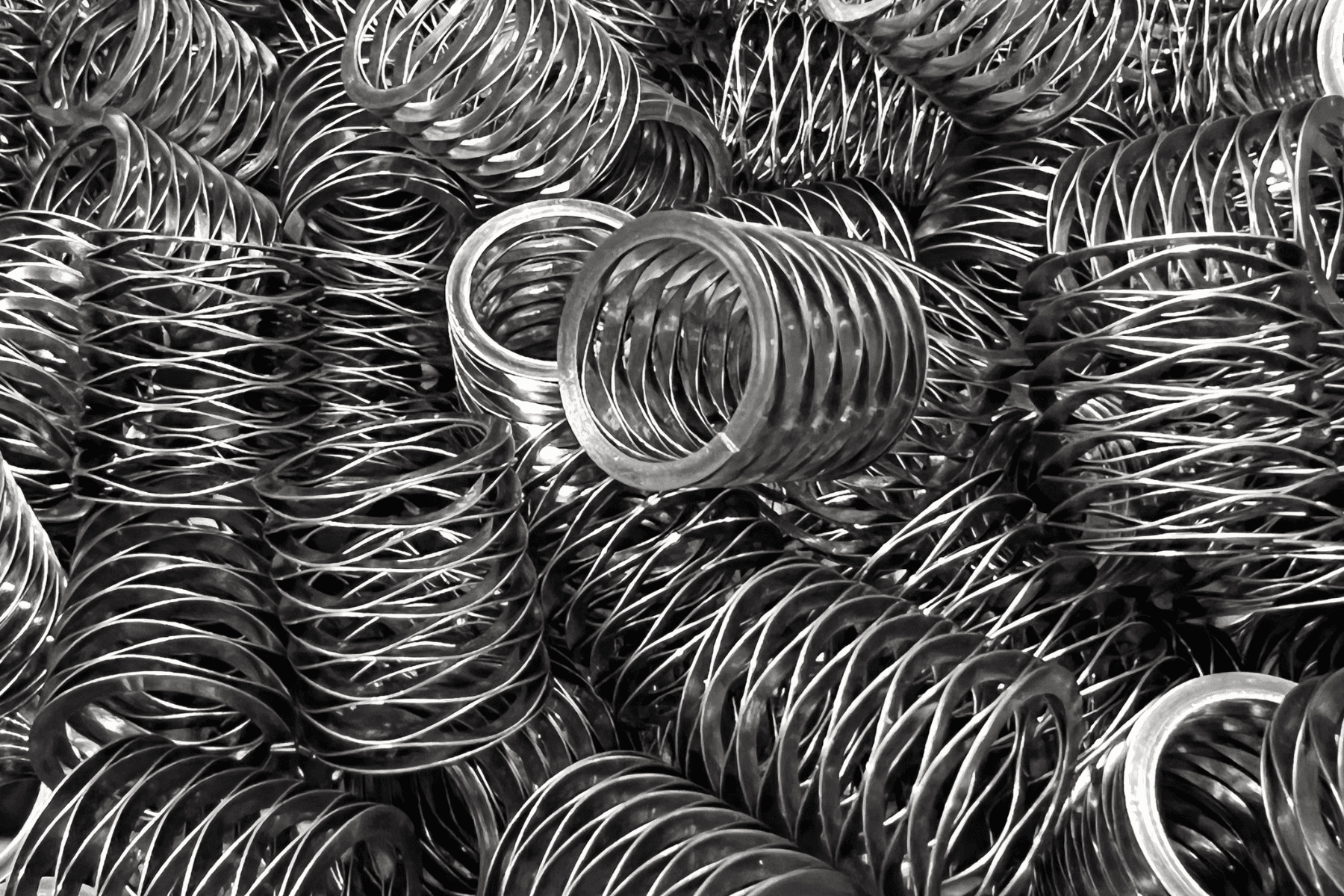

Nested Wave Springs

Ideal for high loads, versatile for extreme applications

High load, low profile springs

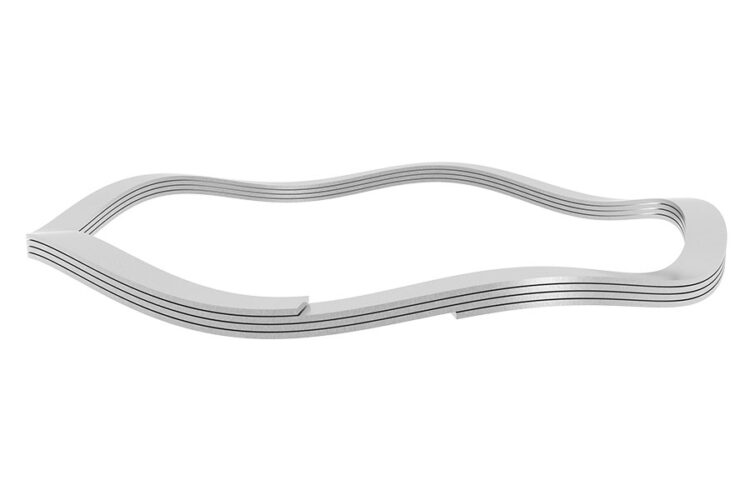

Coiled in parallel, nested wave springs are a continuous coil of layers that produces a wave springs with higher load performance. As the number of turns increases, the loads and spring rates multiply. Nested springs are often specified in applications that require higher static load bearing applications when minimal space is available.

Customizable for specific application requirements.

- Increased # turns, increases spring rate

- Increased # of waves, increases spring rate

- Nearly unlimited load capabilities

- Specialty alloys available for extreme environments (Inconel, Elgiloy, A286 and more)

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.