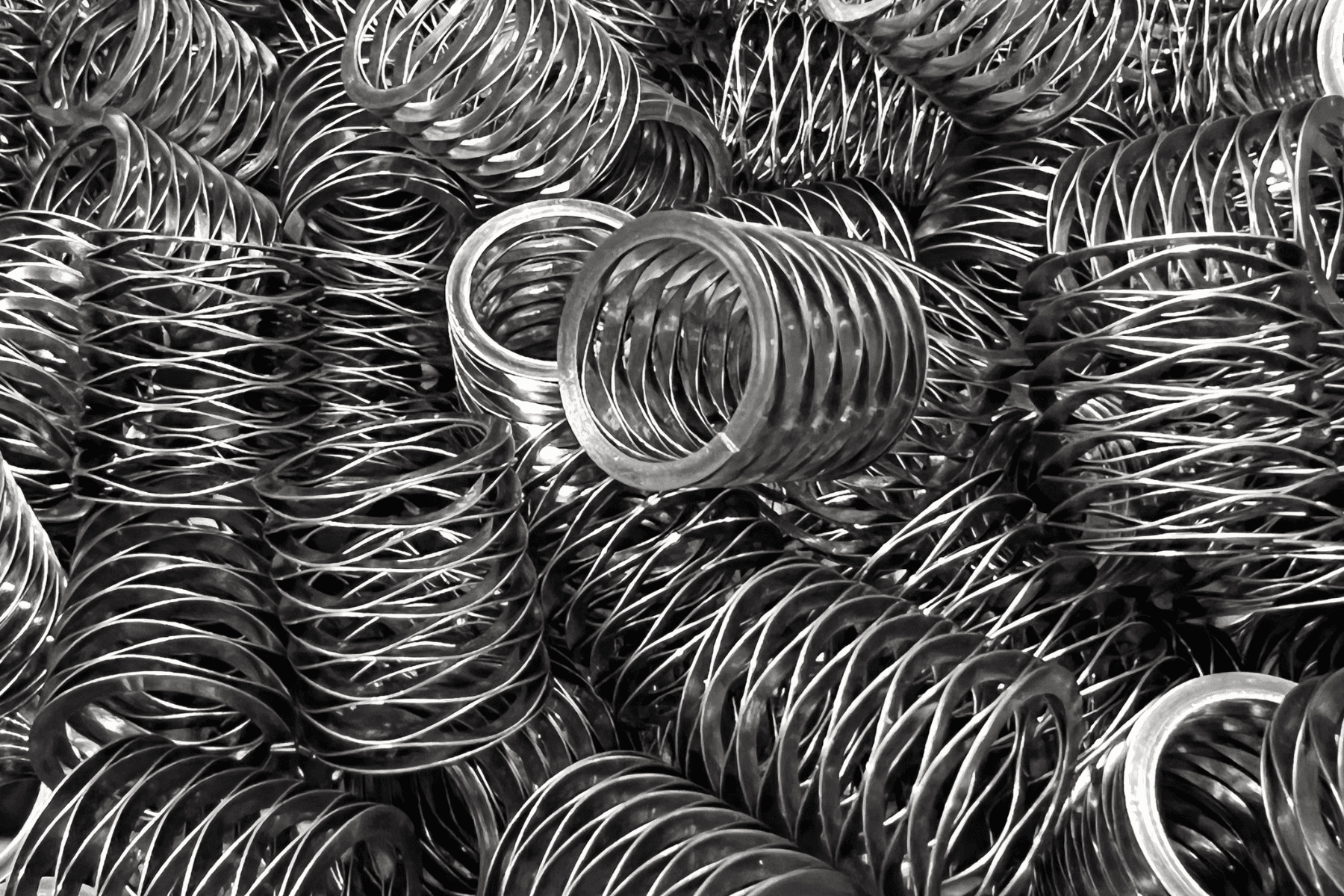

Multi-Turn Wave Springs

Up to 50% axial space savings in your application compared to coil springs.

Multi-turn wave springs typically replace coiled springs or stacks of disc springs and can save up to 50% axial space in an application.

Compact and robust, Multi-Turn Wave Springs can accommodate a wide variety of loads, deflections and diameters. These highly engineered springs can be custom made to exact application specifications, including aspects such as number of waves, wire thickness and end-type configuration.

Technical Advantages

- Multi-turn Wave Springs can save space by up to 50 percent in the axial direction when compared to a coil spring.

- Space savings in radial direction versus other springs with larger diameters.

- One Multi-Turn Wave Spring can replace an array of coil spring.

- Only one spring must be handled, streamlining the assembly process.

- Nearly unlimited range of forces and load capabilities

WSL/WSM/WSR – MULTI-TURN INCH

Used for low to medium force applications with greater travel compared to Single-Turn Springs. Utilizes nearly half the space as helical compression spring while producing the same force.

WSL = Light

WSM = Medium

WSR = Heavy

MWL/MWM/MWR – MULTI-TURN METRIC

Used for low to medium force applications with greater travel compared to Single-Turn Springs. Utilizes nearly half the space as helical compression spring while producing the same force.

MWL = Light

MWM = Medium

MWR = Heavy

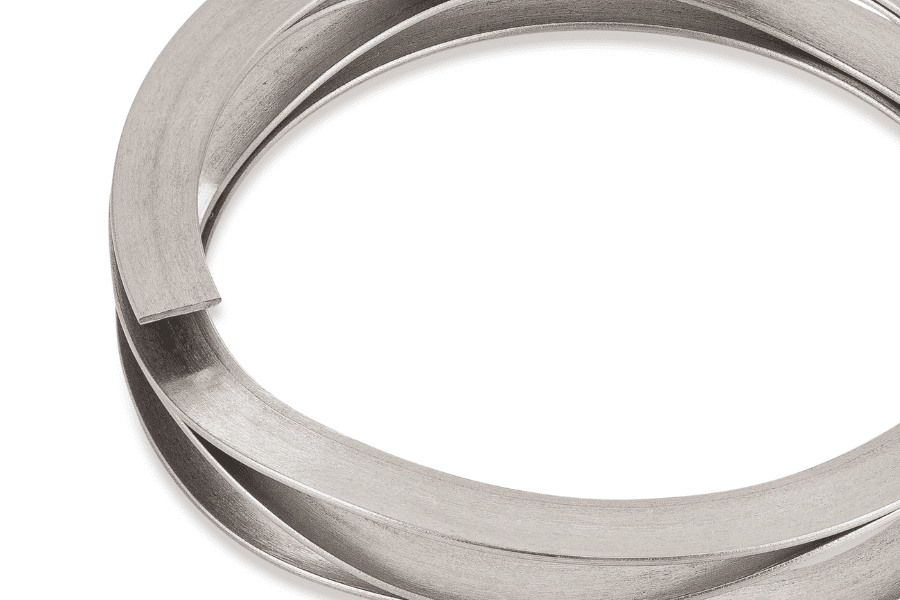

End-Type Configurations

Rotor Clip offer many variations of end type to best suit your application.

Shim Ends

Floating Ends

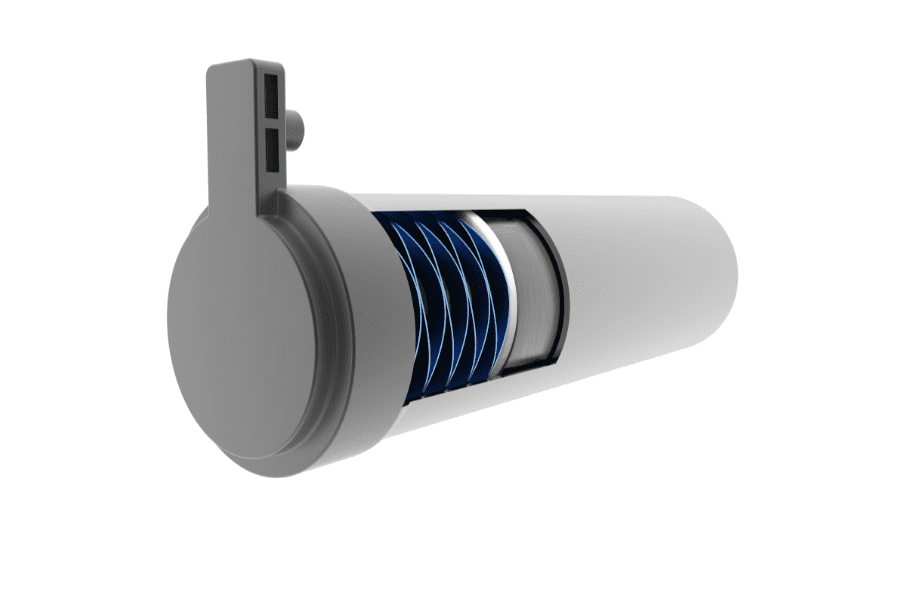

Application Examples

Multi-turn Wave Springs can be found in applications across every industry. Here are some examples.

Downhole Drilling Tool with Multi-Turn Wave Spring

Check Valve with Multi-Turn Wave Spring

Fishing Reel with Multi-Turn Wave Spring

Oxygen Concentrator with Multi-Turn Wave Spring

Fluid Filter with Multi-Turn Wave Spring

Car Mirror with Multi-Turn Wave Spring

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.