Rotor Clip Products

Retaining Rings, Circlips, Snap Rings, Wave Springs, and Hose Clamps

Your Products. Our Passion.

Rotor Clip is your comprehensive manufacturer and supplier of standard and custom retaining rings, wave springs, and hose clamps. With over 20,000 standard parts and custom capabilities, we focus on providing Application Driven Solutions®. Our team of engineers collaborates with you to determine the best product, material, and finish for your application. With manufacturing in the US and Europe, and engineering, customer service, technical sales, and warehouses positioned around the world, Rotor Clip is ready to serve you wherever you are.

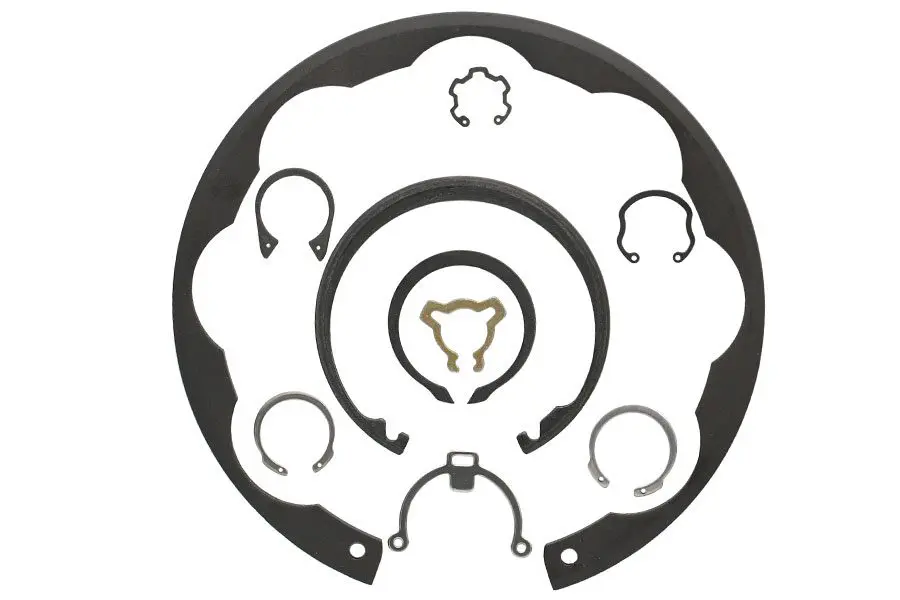

Retaining Rings: Snap Rings, Circlips & Spiral Rings

Every Ring, Every Style, One Manufacturer™

For over 65 years, Rotor Clip has been the only manufacturer of all retaining ring types (snap rings/constant section rings, circlips/tapered section rings & spiral rings), setting us apart from the competition. With our precision manufacturing capabilities in the US and Europe, we offer over 20,000 standard parts, as well as custom parts in sizes ranging from 0.040″ to 47″ (1 mm to 1200 mm) in Inch, DIN, ANSI metric, and JIS. Rotor Clip retaining rings guarantee high-quality performance every time, no matter the industry or environment.

Snap Rings, Circlips, Retaining Clips, Tapered Section Rings, Constant Section Rings —our products go by many names, but they all fall into one of our distinct ring families.

Discover More About Our Retaining Ring, Circlip & Snap Rings

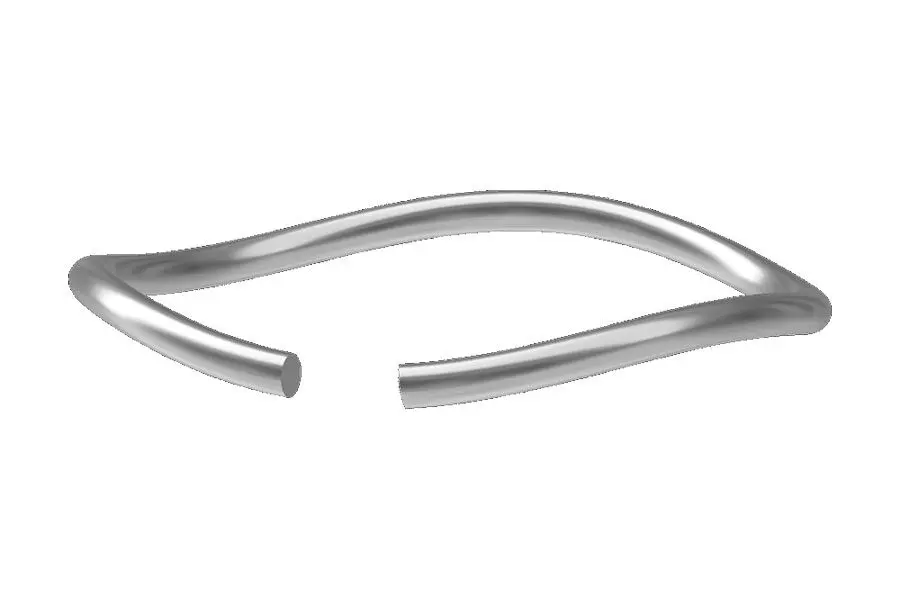

Wave Springs: Single-Turn, Multi-Turn, Round-Wire, Nested & Linear Styles

Save up to 50% Axial Space in Your Application

A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip Wave Springs can make in your applications today.

Choosing the right type of wave spring involves considering factors such as load capacity, cycle life, operating heights, and spring rate. Each type of wave spring is engineered with specific features to address your diverse needs.

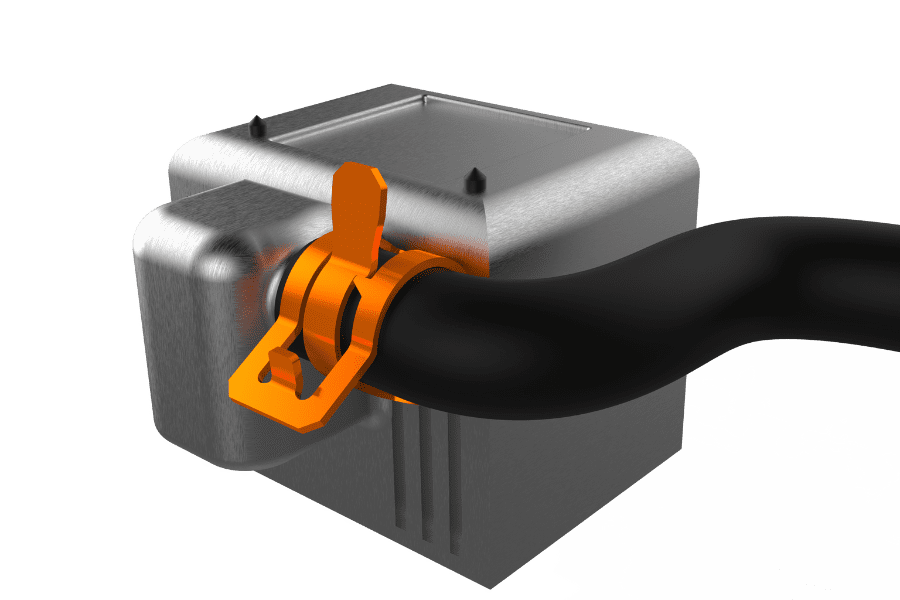

Hose Clamps: Wire & Constant Tension Band Hose Clamps

Eliminate Manual Adjustments In Your Application

Rotor Clip manufactures quality, self-compensating hose clamps for low-pressure applications. Our single wire, double wire, and constant tension band hose clamps expand and contract with temperature changes, eliminating the need for manual adjustments. They are engineered for both pneumatic and manual installation and removal, improving assembly efficiency. Without a screw mechanism, they cannot be over- or under-tightened. All hose clamps are certified to IATF 16949 and ISO 9001:2015 standards.

Rotor Clip hose clamps boasts distinctive design features tailored for specific applications, engineered to make your assembly more efficient.

Common Circlip, Snap Ring, Wave Spring & Hose Clamp Application Examples

Rotor Clip provides Application Driven Solutions™ and have specified and designed circlips, snap rings, wave springs, and hose clamps into every industry and environment.

Automotive Cooling Tank w/ Constant Tension Band Hose Clamp

Bearing Preload w/ Nested Wave Spring

Custom Parts to Meet Your Exact Specifications

At Rotor Clip, we engineer and manufacture custom retaining rings, wave springs, and hose clamps to meet your exact application requirements. From prototype through production, our engineering team works closely with you to create parts that perform reliably and integrate smoothly into your assembly.

To accommodate for unique loads or cycle life, types of modifications include:

-

Load and rotational capacity

-

Tolerance

-

Thickness

-

End configurations

-

Section and thickness

-

Materials and finishes

Retaining Ring & Wave Spring FAQs

Explore Our Most Frequently Asked Questions About Circlips, Snap Rings & Wave Springs Below.

Retaining rings can do the same job for a lot less. A simple groove is all that’s needed to accommodate a retaining ring. Other fastener methods, like nuts, require machining threads, which is more costly, and wastes additional materials. Retaining rings will not require periodic re-torquing as a nut and bolt might. Retaining rings are easier to install than fasteners with multiple components, either manually or in automated assembly equipment, reducing labor costs.

We understand that our products are known by various names in the industry, including circlips, snap rings, retaining clips, and more. At Rotor Clip, snap rings are a specific type of retaining ring with a uniform section, designed to snap into a groove on a shaft or bore to secure components. The broader category of retaining rings includes not only snap rings but also other designs like spiral rings and E-clips. In essence, while all snap rings are retaining rings, not all retaining rings are snap rings.

Wave springs deliver up to 50% tighter force tolerances than standard wave washers and offer more consistent performance. They maintain a more predictable loading throughout a wider range of movement, making them a more reliable choice for. Rather than stacking wave washers, a single wave spring can be used as a single part solution, simplifying assembly and reducing room for errors.

Wave springs generally have lower fatigue rates compared to traditional coil springs, meaning they tend to last longer. When used correctly within their designed deflection range, wave springs can outlast coil springs. They also take up about half the space, which can help reduce both weight and space in your assembly—important factors that contribute to their longer lifespan.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.