White Paper: the Best Springs You Haven’t Tried Yet

|

||

|

Special Feature: White Paper: The Best Springs You Haven’t Tried Yet |

|

|

TECHNICAL CONSIDERATIONS FOR THE SELECTION OF RETAINING RINGS |

||

|

This is the final part of the ongoing Rotor Clip Newsletter Series discussing which retaining rings would work best for different applications. In case you missed parts 1 through 5 you can still catch up by visiting our website, www.rotorclip.com and scrolling to the bottom under our “Currently Trending” section or scroll to the bottom of this page to get caught up. You can also click subscribe so you don’t miss out on other Rotor Clip Newsletters in the future. In part 5 of the Newsletter series issue we discussed beveled rings and their ways of effectively taking up end play. In this final segment we discuss which self-locking ring is the best for your application needs. |

||

| Part 6 of 6 : SELF-LOCKING RINGS ON UNGROOVED SHAFTS |

||

|

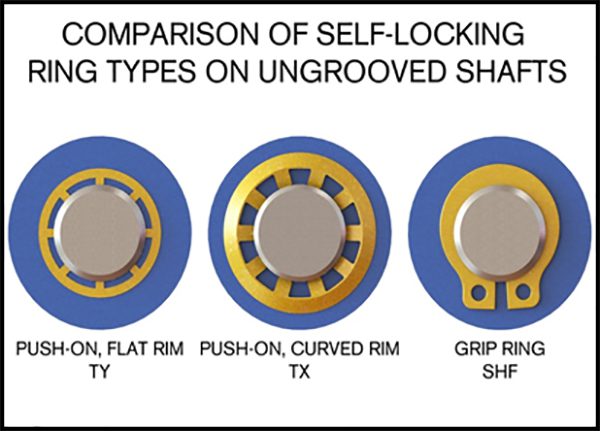

Self-locking retaining rings are used on shafts without grooves. The simple circular ring at the left of Figure 8 has a flat rim and will support moderate static loads. It is used widely because of its relatively small outside diameter. The reinforced circular self-locking ring next to it has a curved rim and will handle greater loads even if some vibration is present. However, it has a larger outside diameter. These two rings work on the same principle: the prongs resist counter-pressure by digging lightly into the shaft. The fasteners can be moved, therefore, in one direction only. They should be used on non-hardened/soft shafts and, in most cases, must be destroyed to be removed. |

||

| Figure 8 | ||

| In this respect, the grip ring shown at the right has an outstanding advantage. It can be moved in either direction and its position can be adjusted after installation by using retaining ring pliers that fit into the lug holes. Therefore, the ring can be used over and over again. These characteristics make it more suitable for applications where components may have to be disassembled for repair or maintenance.

Thanks for reading our Technical Considerations for the Selection of Retaining series. Whatever the fastener requirement, you can find a retaining ring that can meet it. The challenge is to find the right one that will perform according to your specifications and deliver the expected economies. Considering the rings described in this series is a solid first step to achieving that objective. Below are links to the past newsletters of the series, and remember to subscribe so you do not miss out on other Rotor Clip Newsletters. |

||

|

|

||

| VIEW PART 5 of 6: Beveled Retaining Rings | ||

Subscribe to Receive Our Monthly Newsletter |

||

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.