Wave Springs in a Nutshell

|

||

|

Wave Springs in a Nutshell |

||

|

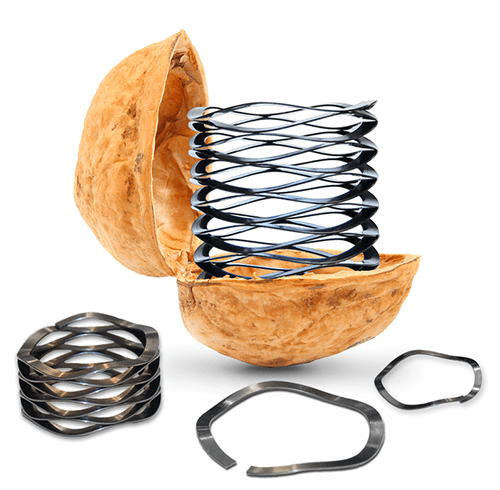

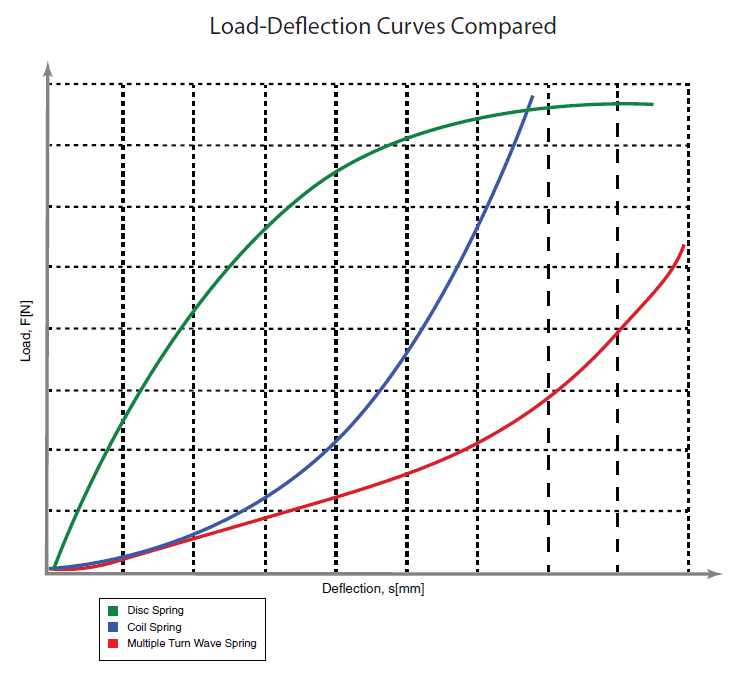

Most engineers have plenty of experience with traditional coil and disc springs, while single- and multi-turn wave springs remain something of a mystery. Yet wave springs, particularly those made from flat wire, should be better known given their compelling engineering advantages. Chief among these advantages is an excellent force-to-work height ratio. Well-designed wave springs can produce the same or even greater forces as coil springs whose work heights are up to twice as large. |

||

|

As drop-in replacements for traditional spring elements, wave springs can improve the performance of spring-loaded components. But to maximize the engineering potential of wave springs, you should design around their unique qualities, which include: |

||

|

|

|

|

At Rotor Clip, we produce wave springs in a vertically integrated manufacturing environment—in which we roll our own flat wire and form it in our own machines. Vertical integration allows for fine adjustments in spring designs in response to minor batch to batch variations in raw material to maintain targeted performance characteristics. It also allows us to keep tight statistical control on all the rolling and coiling processes. When it comes to wave springs, the importance of this manufacturing expertise can’t be understated. So it pays to specify high-quality springs. If you do, you’ll be able to take advantage of all the design benefits wave springs can offer. —————————————— For a more detailed look at wave springs please download our white paper |

||

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.