Technical Considerations for the Selection of Retaining Rings

|

||

|

TECHNICAL CONSIDERATIONS FOR THE SELECTION OF RETAINING RINGS |

||

|

This is part 3 of a 6 part Rotor Clip newsletter series about which retaining rings work best with different applications. Click Part 1 or Part 2 if you would like to catch up. In this month’s news letter, explanations of Standard vs Heavy Duty rings are discussed as well as the efficient C and E rings Rotor Clip offers. |

||

| Part 3 of 6 : Standard vs. Heavy Duty | ||

|

|

||

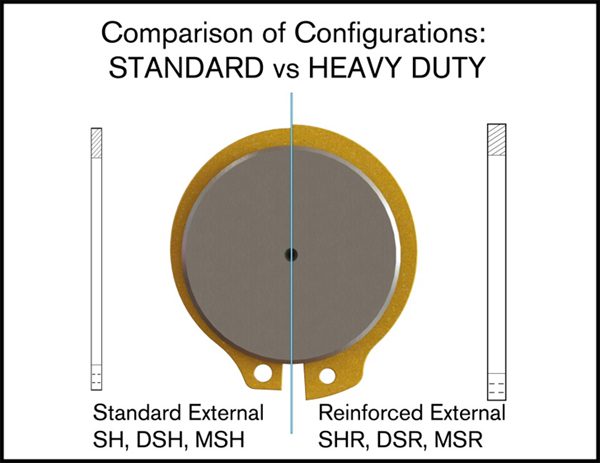

| Figure 4 | ||

| In cases of very heavy loads, the reinforced ring, shown at the right half of Figure 4, will out-perform the basic ring, shown on the left half of Figure 4 because of its greater section height, lug shape and thickness. These rings may also remedy instances of fatigue failure. | ||

|

|

||

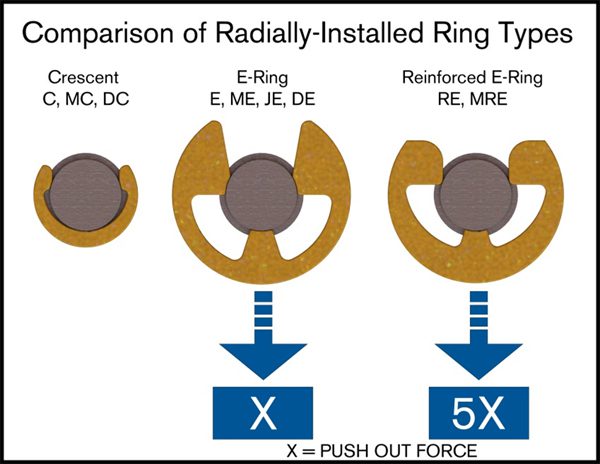

| Figure 5 | ||

|

Radially installed rings also differ. The Crescent (“C”) ring at the left in Figure 5 is preferred where space is at a premium and loads are not very heavy. (They are also more tamper resistant). The E-ring in the middle is ideal for large shoulders, whereas the reinforced E-ring at the right functions best for applications characterized by high vibration, RPM and cyclic loads. |

||

|

|

||

| VIEW PART 2 of 6: Standard vs Inverted | ||

Subscribe to Receive the Remaining Parts of this Series |

||

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.