Rotor Clip Plates its Rings Using a Mechanical Plating Process Instead of an Electroplating Process.

Rotor Clip Plates Its Rings Using a Mechanical Plating Process Instead of An Electroplating Process. Here’s Why:

Electroplating dramatically increases the risk of hydrogen embrittlement

It’s a good question to ask a supplier whether you’re buying retaining rings or any kind of fastener.

Are my parts being electroplated or mechanically plated?

When parts are electroplated, hydrogen gas (from the water of the electroplating solution) gets “plated” onto the surface of the parts along with the metal that is deposited there.

But this hydrogen gas actually gets driven into the depths of the steel. This happens because the atoms of hydrogen are the smallest known to man, and they easily penetrate throughout the steel.

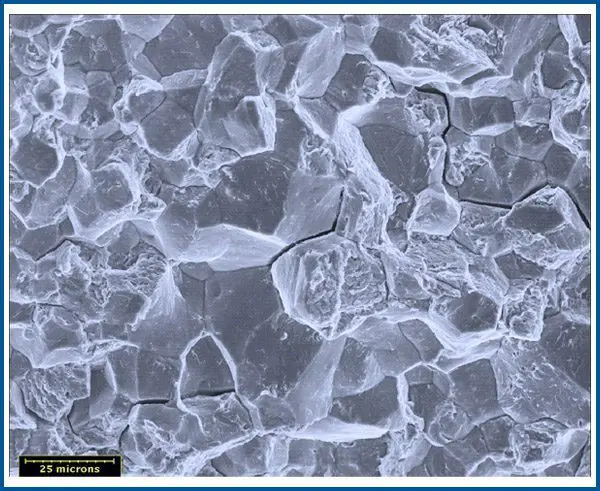

Once inside the steel, these atoms tend to come together to form “bubbles,” just as soap bubbles do. These bubbles find their way into tiny voids within the steel and develop tremendous pressure in these small areas. Normally, the steel is strong enough to withstand this pressure when the parts are lying idle. But the moment the steel is slightly deformed, or put under stress, the “bubbles” are released, explosively. This fractures the steel parts as if they were brittle. The same condition can occur from acid pickling of steel.

Microscopic fracturing of steel

It can be cured by baking the parts before they are actually used. This causes the hydrogen to leave the steel gradually without permanent damage. However, this adds another step to the process, which ultimately adds to your cost.

This condition–of hydrogen absorption from the plating solution which makes the steel fail in a brittle manner when stressed–is called hydrogen embrittlement.

During the mechanical plating process, on the other hand, the metal that is ultimately deposited on the surface is in the form of a powder. The powder is essentially cold-welded to the substrate as a result of the impact of glass beads or other suitable media which delivers the plating energy. Hence the names “peen plating or impact plating” are sometimes used to describe this process. No direct electrical energy is used to drive the deposit onto the substrate. In fact, the only electrical energy required during the entire process is to turn the barrel that houses the parts and the media.

Since mechanical plating does not use electricity to drive the hydrogen into the steel, there is no danger of embrittlement in the process.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.