Rotor Clip Offers Inch and

|

||

|

|

|

|

|

ROTOR CLIP OFFERS INCH AND METRIC RETAINING RINGS

|

||

|

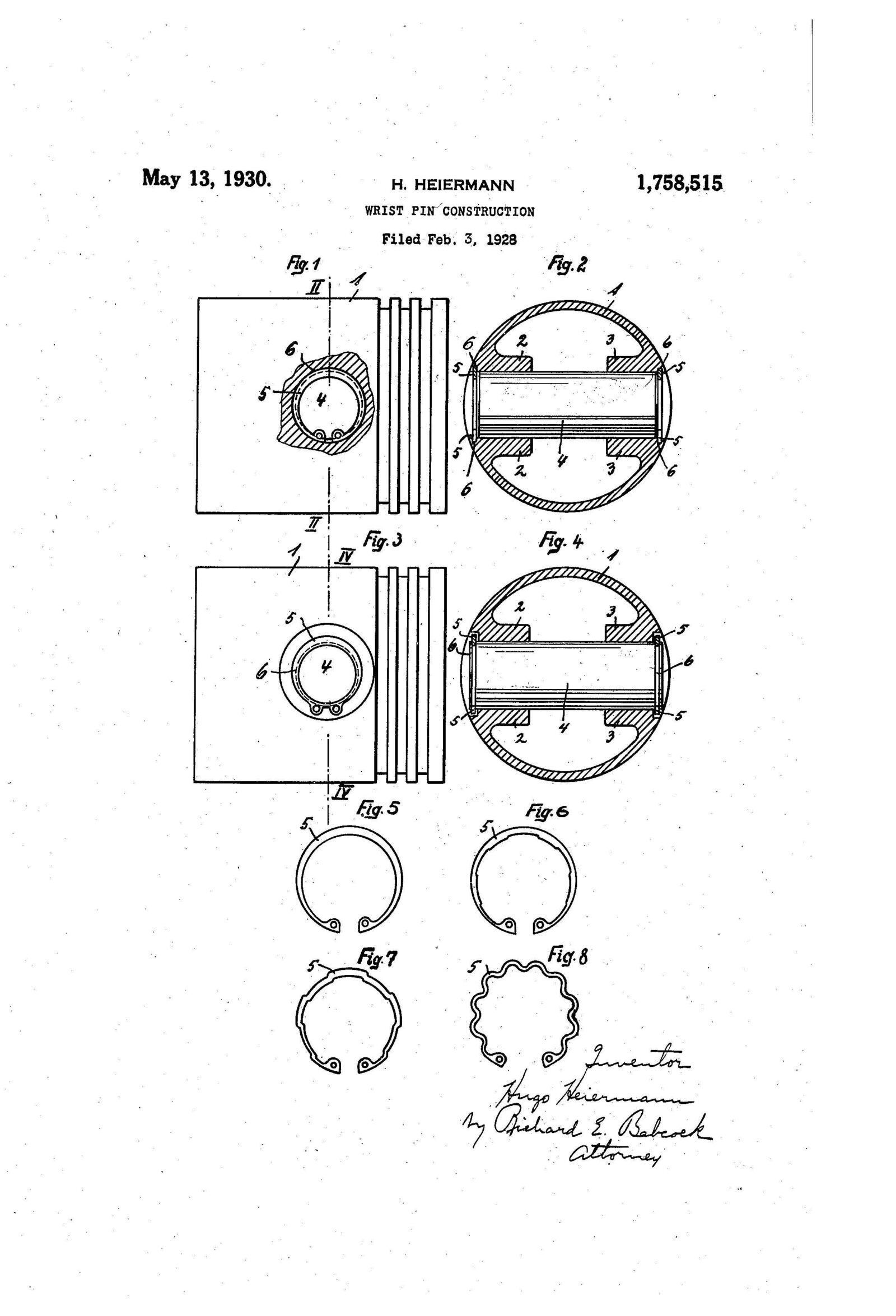

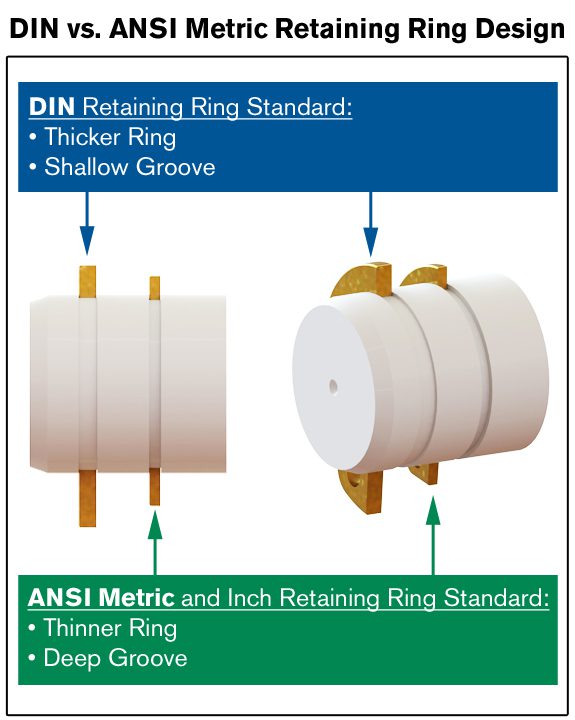

The retaining ring was invented in Germany nearly 100 years ago when Hugo Heiermann, a German engineer, noticed traditional methods of securing a wrist pin to a piston sometimes failed causing axial movement of the pin and, ultimately, damage to the cylinder wall. He was granted a patent for his device in 1930 and the retaining ring soon gained popular acceptance throughout Europe during the next few decades. The retaining ring was always manufactured to DIN metric standards, since it was virtually unknown in the US. The original metric design called for a thicker ring that seated in a shallow groove. The rationale for this was that an unexpected overload would dislodge the ring from the groove without damaging the shaft or housing. |

||

Click Image To Enlarge |

The US began manufacturing retaining rings in 1942 as part of the war effort. These were made to inch standards and, unlike the metric approach, US engineers sought to make a thinner ring that would fit in a narrower, deeper groove. The logic was that in the event of an overload the shaft or housing would fail first, thus minimizing damage to the retained components. Obviously, there was always contention between the two schools of thought. The issue was brought to a head in the 1970’s when the US retaining ring industry tried to meet the competitive challenge of the metric system as it related to retaining rings. Their response: an ANSI metric line of retaining rings, which were essentially those inch rings that converted satisfactorily to metric dimensions. The series seemed to embrace the best of both worlds: a thinner ring seated in a deeper groove that conformed to metric dimensions and tolerances. |

|

|

But Robert Slass, who was President and owner of Rotor Clip at the time and part of the committee that developed AINSI metric rings, didn’t feel it was sufficient to satisfy future customer requirements. He knew the ANSI metric line was limited and that you couldn’t serve these industries without a DIN metric line of retaining rings. Slass decided to give customers an alternative and let them choose. He began tooling an entire DIN metric line. It was quite a gamble at the time, but it paid off in the long run. His tooling of the DIN line enabled Rotor Clip to compete in the global market. Regardless of the standard, Rotor Clip can now provide the design engineer the right retaining ring for the application whether it needs to conform to DIN metric, ANSI metric or inch standards. Click Here To View Our Full DIN And ANSI Metric Product Line. |

||

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.