Materials

|

|

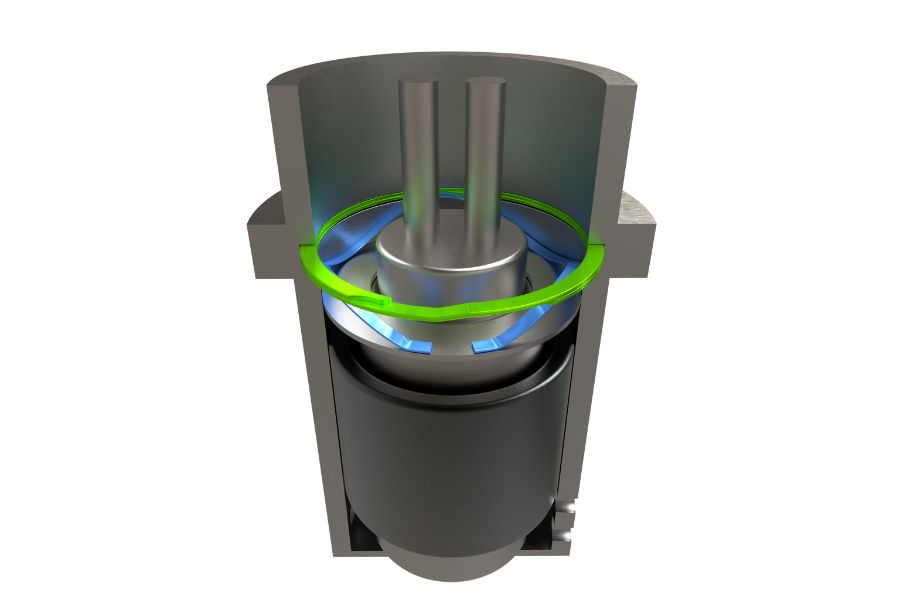

Spiral retaining rings provide a reliable, artificial shoulder by securely seating into a groove on shafts or inside housings. Unlike traditional stamped rings (tapered section, circlip, constant section, snap ring), spiral rings are coiled from flat wire, offering 360° continuous contact in multi-turn configurations for enhanced load distribution. This coiled design eliminates the need for assembly lugs, saving space while maintaining precision and durability, making them ideal for demanding applications.

Rotor Clip’s spiral rings are the trusted choice, offered in a wide range of sizes, materials, and finishes as a standard, with almost limitless customization options to meet your specific needs. All our spiral retaining rings are manufactured in-house, from raw materials to finished product. Whatever your requirement, we will find the right ring for your application, and if we don’t have it, we’ll collaborate with you to create one!

Rotor Clip spiral rings are available in diameters from:

Rotor Clip spiral rings are available in a diverse range of standard and specialty materials to meet your specific application requirements. Whether you need stainless steel, Inconel, or beryllium copper, our expert engineers utilize metallurgical expertise to ensure your spiral rings provide exceptional strength and performance.

|

|

|

At Rotor Clip, we’re here to help you every step of the way to customize your spiral retaining rings. Whether you need adjustments in load capacity, rotational tolerance, end configurations, section thickness, or specific materials and finishes, we’ve got you covered. From start to finish, we ensure your rings meet your exact needs.

Spiral retaining rings are simple to install and remove. No special tools are required for assembly as the rings can be wound into the groove, however simple tooling allows for high-speed, automated assembly. For removal, spiral rings are provided with a removal notch or scallop, a basic screwdriver can be used to access the notch and wind the ring out of the groove.

Locate the groove

Guide Spiral Ring into groove on bore

Separate spiral ring to fit end into groove

Snap Spiral Ring into groove (use screwdriver if needed)

Installation Complete

Explore More Frequently Asked Questions About Retaining Rings

A spiral retaining ring is a coiled fastener used to secure components within mechanical assemblies. It is designed to seat into a groove on a shaft or inside a housing. Unlike traditional stamped retaining rings, spiral rings provide continuous 360° contact for better load distribution and eliminate the need for assembly lugs. They are commonly made from carbon steel or stainless steel, and exotic alloys (Elgiloy, Inconel and Hastelloy), and are ideal for applications requiring precision and durability.

Spiral retaining rings are simple to install and remove, requiring no special tools for assembly. To install, simply locate the groove and guide the spiral ring into place. You can effortlessly twist the ring into the groove using just your hands, or, for automated processes, spiral rings can be assembled on production lines. The smooth edges of the ring minimize the risk of scratching your assembly and make it easy to handle. When it’s time for removal, a screwdriver is all that’s needed to extract the ring using the removal notch, making maintenance and repairs quick and hassle-free.

For high-temperature environments, stainless steel, particularly grades like 17-7 PH or 300 series, is commonly used due to its excellent strength, corrosion resistance, and ability to retain mechanical properties at elevated temperatures. In more demanding applications, alloy steels or other specialized materials may be selected based on the temperature range and other environmental factors.

For assistance on selecting the right material, contact our team now.

Resources

Explore some of our most popular resources about retaining rings, snap rings, spiral rings, and circlips.