New: Surface Friendly Wave Springs

|

|

|

NEW: SURFACE FRIENDLY WAVE SPRINGS Another step towards improving bearing life. |

|

|

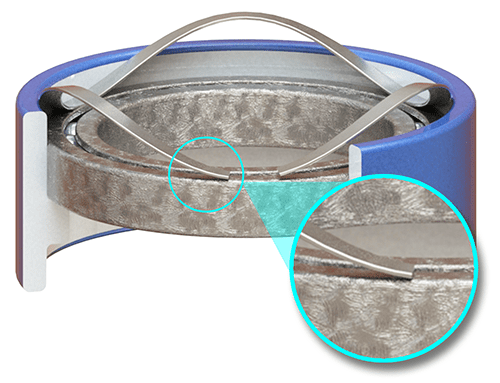

Engineers like to select a spring with a high axial load to reduce vibration and noise to ultimately prolong bearing life. The design of standard single turn wave springs with gap features sharp corners at the cut off area of the spring ends. But the sharp corners can scratch the surface of the bearing as well as the mating parts when the wave form shows a steep incline depending on the load specification. This debris can lead to failure of the bearing as well as the entire application. |

|

|

|

| Standard single turn wave spring with sharp end corners contacting mating assembly. | |

|

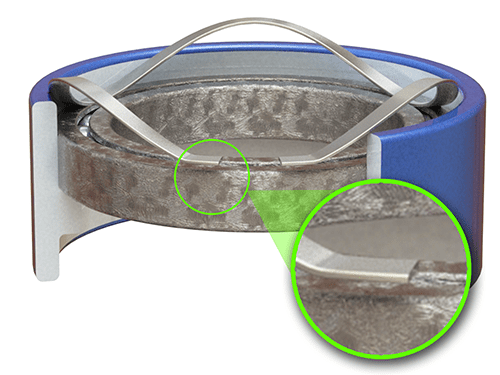

Rotor Clip’s patent-pending design solves this problem by flattening the ends of the spring so that they will not create excessive wear that can damage the application. As with all of our wave spring designs, there is No Tooling Cost for custom designs with this end feature. For more information on this new wave spring design and its application opportunities please contact info@rotorclip.com |

|

|

|

|

Patented single turn wave spring design with flat ends rest smoothly against mating assembly. |

|

|

|

|

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.