Technical Considerations for the Selection of Retaining Rings

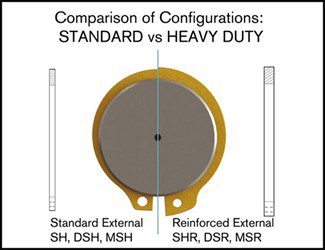

Standard vs. Heavy Duty

Figure 4

In cases of very heavy loads, the reinforced ring, shown at the right half of Figure 4, will out-perform the basic ring, shown on the left half of Figure 4 because of its greater section height, lug shape and thickness. These rings may also remedy instances of fatigue failure.

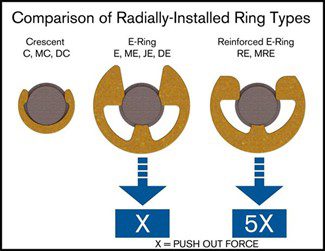

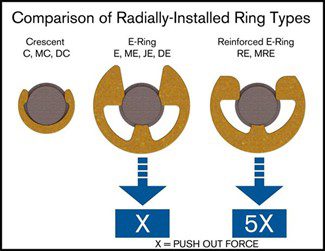

Figure 5

Radially installed rings also differ. The Crescent (“C”) ring at the left in Figure 5 is preferred where space is at a premium and loads are not very heavy. (They are also more tamper resistant). The E-ring in the middle is ideal for large shoulders, whereas the reinforced E-ring at the right functions best for applications characterized by high vibration, RPM and cyclic loads.

The reinforced ring is interchangeable with the E-ring but grips the groove bottom with 3-5 times the radial force and has greater resistance to fatigue failure. In most cases, its outside diameter/shoulder is larger than the E-ring’s, which is another factor to consider. All three styles are available in taped cartridges for assembly with dispensers and applicators.

For more help deciding which ring would best fit your application, Contact Us and ask for a Technical Salesman.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.