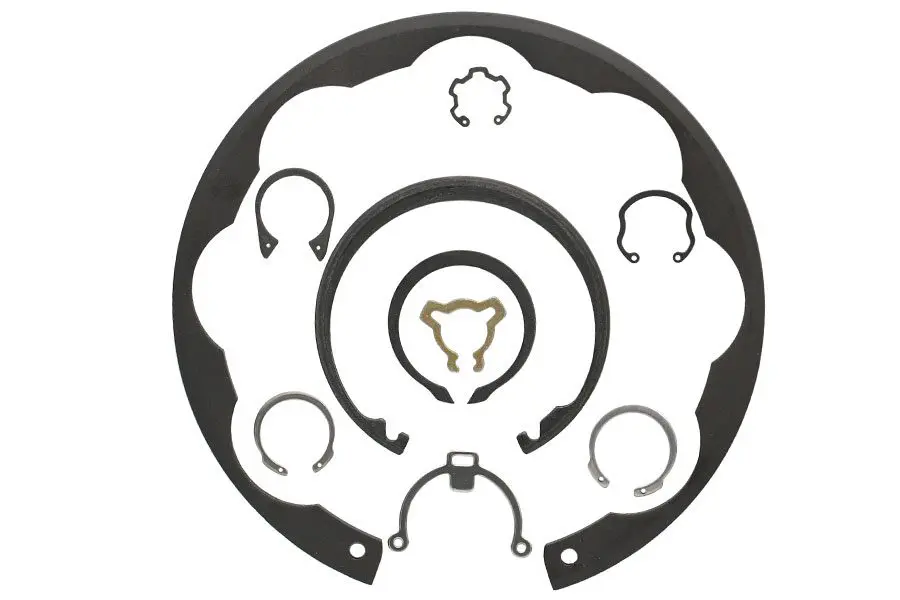

We Exceed Compliance & Quality Standards

We are committed to providing our customers with a quality product 100 percent of the time. To support this goal, we adhere to strict regulatory requirements and quality standards, followed by ongoing product testing and continuous improvements.

Our in-house lab conducts comprehensive product tests, pivotal for our Production Part Approval Process (PPAP) submissions and First Article Inspection Reports (FAIR). We uphold our reputation with certifications including ISO 9001, ISO 14001, IATF 16949, AS9100 and ISO 13485.

Learn more aout Rotor Clip Quality Control