MHO-175

Looking for a specific material or finish? View complete part numbers and request a quote below.

Specifications

Part Data

- Housing or Shaft Housing

- Axial or Radial Axial

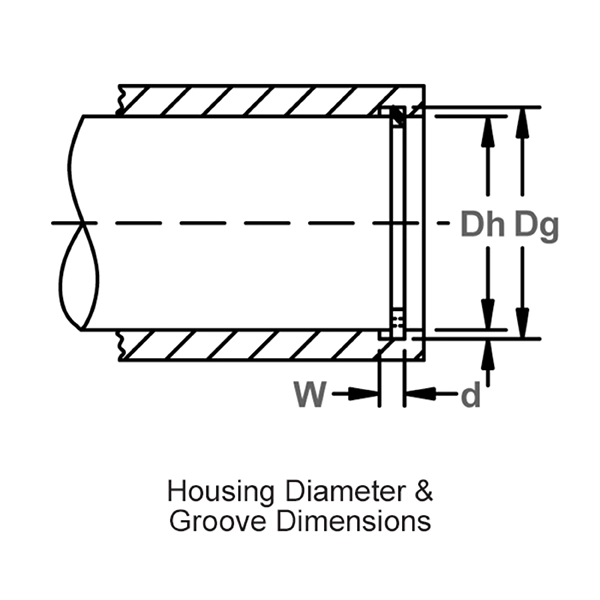

- Housing Dia. Dh 6.890 inches

- Dh mm 175.000 mm

- Groove Diameter Dg 183.200 - 183.700 - mm

- Groove Width W 4.250 - 4.500 - mm

- Groove Depth D 4.100 mm

- Free Diameter Df 189.250 - 193.350 - mm

- Thickness T *** 3.880 - 4.120 - mm

- Lug Height H 13.500 mm

- Maximum Section S Max 11.600 mm

- Minimum Section S Min 5.700 mm

- Hole Diameter R 4.600 mm

- Weight Per 1000 Pcs. 147.000 kg

- Edge Margin Y Min. 12.300 mm

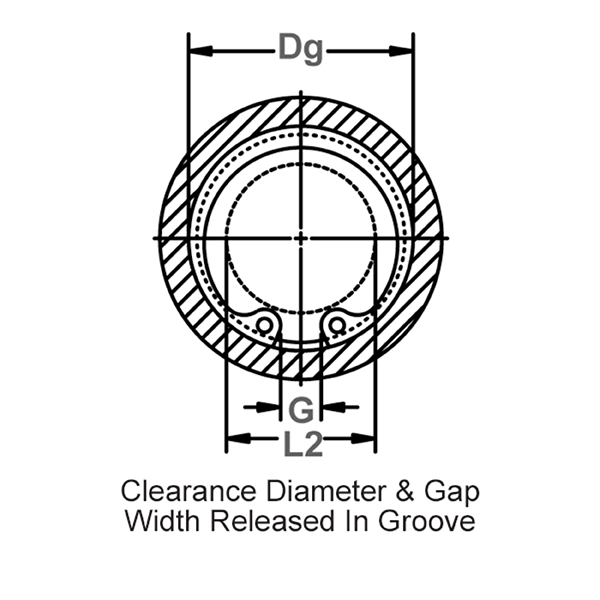

- Clearance Dia. Compressed In Housing L1 146.000 mm

- Clearance Dia. Released In Groove L2 154.200 mm

- Gap Width Ring In Groove G 37.700 mm

- Hardness ST 48.000 - 52.000 - HRC

- Hardness SS 44.000 - 51.000 - HRC

- Interchange Waldes Truarc 10-100 1750

- Interchange IRR

- Interchange Anderton

- Interchange Mil Or Aero

- Interchange Din

Performance Data

- Thrust Ld. (lbs.) Ring Safety Factor Of 4 Pr 670.000 kN

- Thrust Ld. (lbs.) Groove Safety Factor Of 2 Pg 403.000 kN

Tool Data

- Ratchet Pliers (w/o Tips) RP-1100

- Straight Ratchet Pliers Tips RP-71001R

- 45 Ratchet Pliers Tips RP-71451R

- 90 Ratchet Pliers Tips RP-71901R

Product SKUs

Product SKUs listed may not include all available options. If you don't see what you're looking for, or need help selecting the right part, please contact us.

Materials and Finishes

Materials

- Carbon Steel (SAE 1060-1090)

- Stainless Steel (PH15-7 Mo, PH17-7)

- Beryllium Copper

- Special Material Grades

Finishes

***For plated rings, add .002" (.05 mm) to the listed maximum thickness.

- PA - Phosphate, Carbon Steel

- PD - Phosphate and Oil, Carbon Steel

- PAL - Phosphate with Sealer, Carbon Steel

- HPD - Heavy Phosphate and Oil, Carbon Steel

- ZD - Zinc Plating, Carbon Steel

- ZF - Zinc Bright, Carbon Steel

- ZDL - Zinc Dichromate with Sealer, Carbon Steel

- HZDL - Heavy Zinc Dichromate with Sealer, Carbon Steel

- Z3X - Trivalent Chromate over Zinc, Carbon Steel

- ZFF - Zinc Flash, Carbon Steel

- CF - Copper Flash, Carbon Steel

Documentation

Description

MHO retaining rings are axially assembled internal ANSI metric circlips and are part of Rotor Clip’s tapered section retaining ring line. Once installed into the groove of a housing/bore, the portion of the ring protruding from the groove acts as a shoulder to securely hold an assembly in place by preventing axial movement along the bore.

More than Parts. A True Partnership.

Our passion is creating the best rings, springs, and clamps. Our mission is to make your work a success. We are here for you.