Retaining Rings: Circlips, Snap Rings, Spiral Rings & Wave Springs for the Aerospace Industry

You’re rising to new heights. You can count on our partnership.

Helping Keep Aircraft Flying, One Part at a Time

There’s no “good enough” in the aerospace industry. Every part, from the biggest to the smallest, has to perform exactly as designed. Rotor Clip has met this challenge for nearly 70 years, supplying AS9100-certified retaining rings, snap rings, spiral rings, and wave springs for aircraft, space, and defense systems.

With global manufacturing, in-house engineering support, and decades of experience, Rotor Clip provides more than parts for aerospace. We deliver the trusted solutions engineers rely on to keep systems operating safely and reliably.

Aerospace Applications for Rotor Clip Retaining Rings and Wave Springs

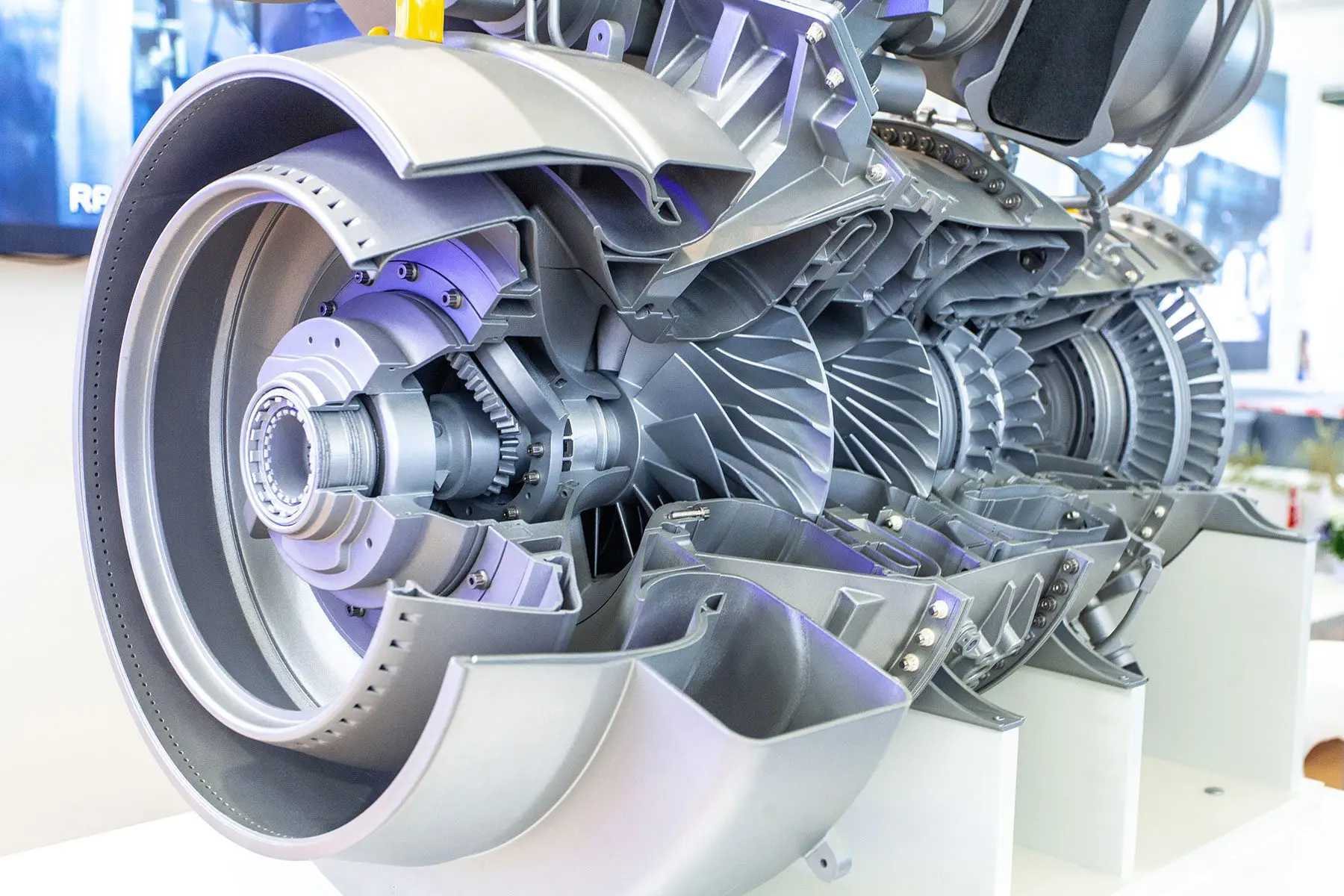

From engine and landing gear to electrical assemblies and cabin mechanisms, Rotor Clip retaining rings and wave springs quietly deliver alignment, stability, and smooth operation under extreme temperatures, intense vibration, and high-speed rotation. Though often hidden inside a system, they help maintain assemblies and ensure dependable performance, flight after flight.

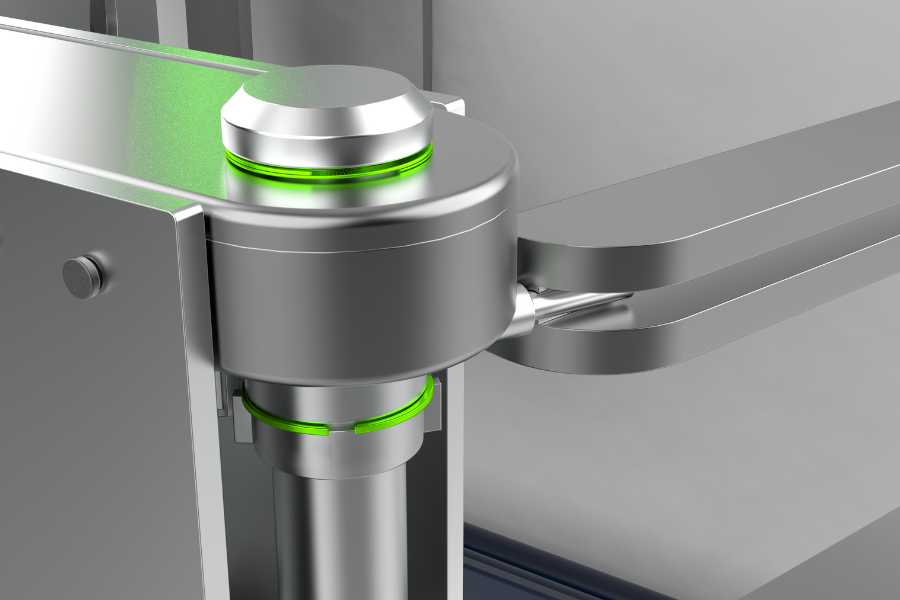

Aircraft Entry Door with Snap Ring & Spiral Rings

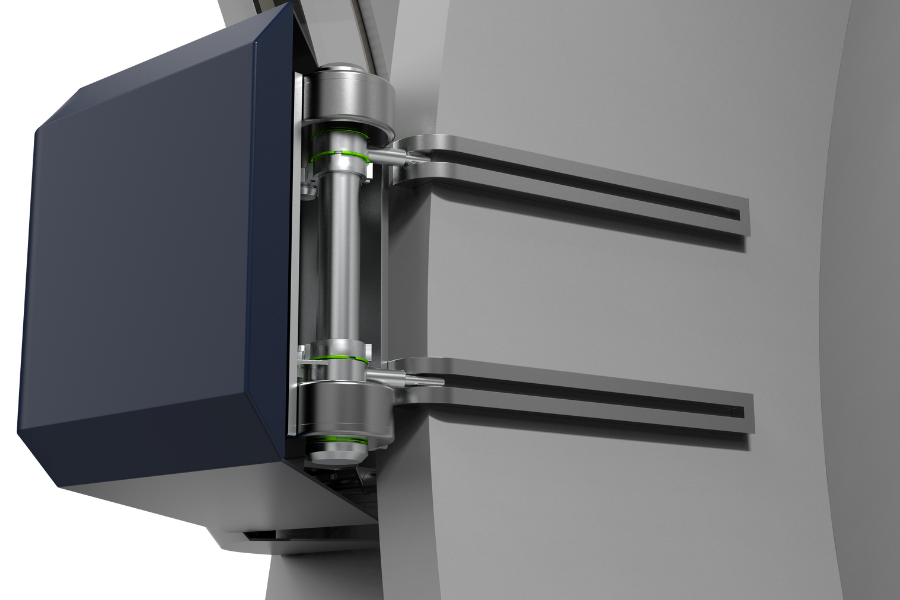

Front Landing Gear with Spiral Rings & Circlips (Tapered Section Rings)

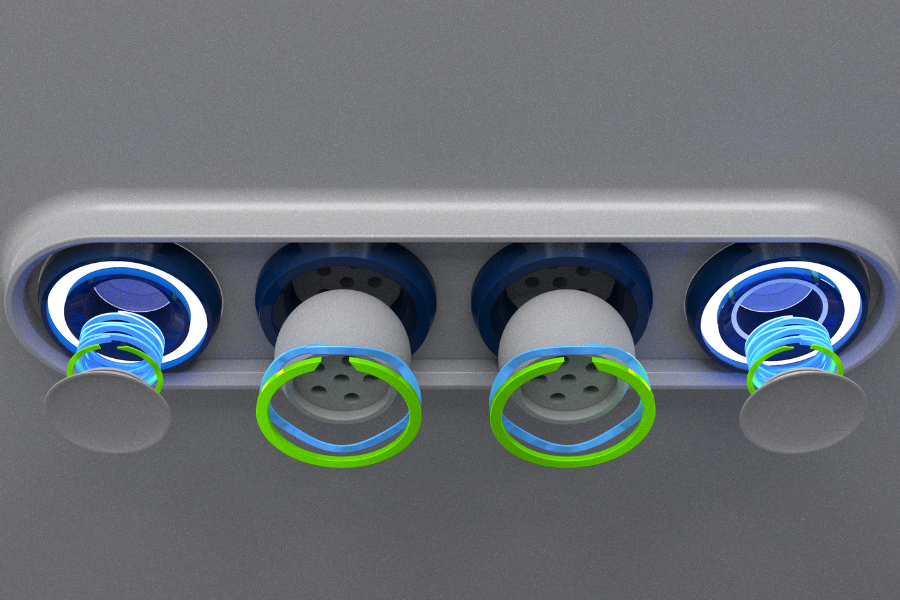

Interior Control Panel w/ Spiral Rings, Single-Turn Wave Springs & Multi-Turn Wave Springs

Other Popular Aerospace Applications for Retaining Rings and Wave Springs

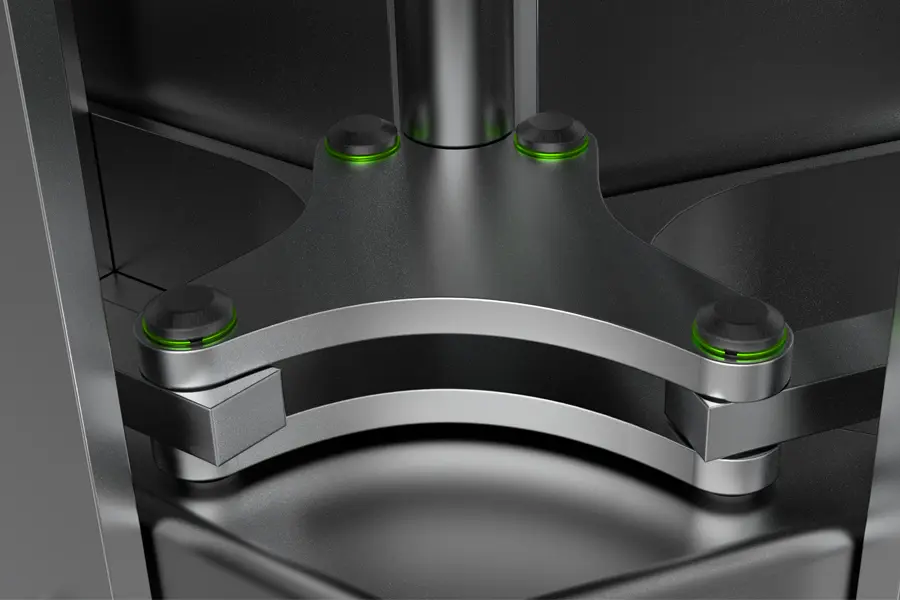

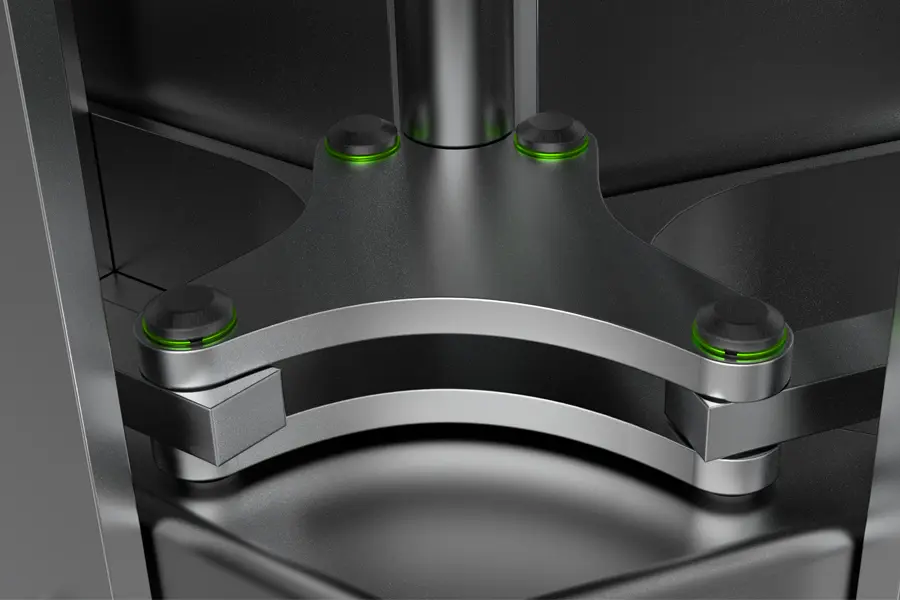

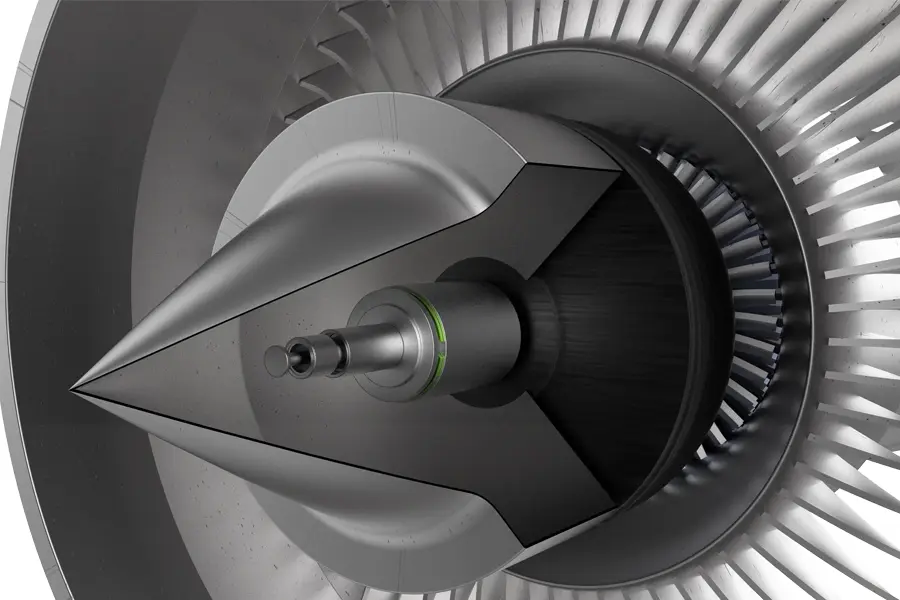

Engine with Snap Ring (Constant Section Ring)

Interior Attendant Area with E-Ring

Electric Bay with Single-Turn Wave Spring

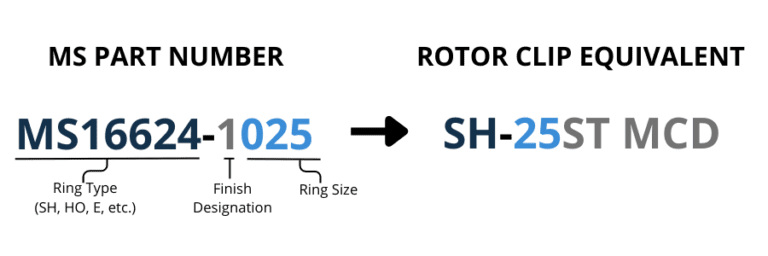

Competitor and MS Part Interchange

Cross-Reference Retaining Ring & Wave Spring Part Numbers

You can search for aerospace/military parts directly in our product search feature, which automatically cross-references them with Rotor Clip equivalents.

Download our interchange chart to quickly convert military and competitor aerospace parts to Rotor Clip part numbers.

High-Performance Ring & Spring Materials

Rotor Clip retaining rings, circlips, snap rings, spiral rings, and wave springs are available in a wide range of high-performance materials and finishes, stocked in our US and EU warehouses for immediate access. Engineers can rely on our extensive inventory and knowledgeable support teams to select the right material and finish for every aerospace and defense application.

Common Materials for Aerospace Applications Include:

- Spiral Retaining Rings: Spring Steel (SAE 1070-1090) and AISI 302 stainless steel.

- Wave Springs: 17-7PH Cond. CH900 stainless steel, often passivated to AMS2700 for enhanced corrosion resistance.

Materials for Military or Specialized Applications:

- Carbon steel with cadmium plating for durability and corrosion protection.

- Black oxide finishes for specialized or camouflage applications.

Looking for other materials? Rotor Clip has them available. Inquire about custom materials now.

Resources

AS9100 Certified to Manufacture for the Aerospace Industry

All our products are manufactured in accordance with the relevant standards. Our commitment to them is at the heart of our mission. Rotor Clip is certified and registered to AS9100, ISO 9001, ISO 14001, IATF 16949 & ISO 13485

Your Trusted Partner From Part Design to Final Takeoff

Rotor Clip provides hands-on engineering support at every stage of your project. Our team works alongside yours from initial part and material selection through installation, providing guidance on complex designs, application requirements, and unique challenges.

With nearly 70 years of experience working directly with aerospace engineers, we understand the demands of critical applications and deliver parts that perform under the most stringent conditions. When standard parts cannot meet specifications, our in-house capabilities in the US and EU allow us to design, prototype, and manufacture custom retaining rings, snap rings, spiral rings, and wave springs to your standards.

With strategically positioned hubs and stocked warehouses, we provide rapid access to materials and parts, keeping projects on schedule.

Trust Rotor Clip as your partner for aerospace and defense projects, providing solutions that meet precise specifications with confidence.

Application Spotlight: Drone with E-Ring

In this drone application, the Rotor Clip E-ring securely holds the motor shaft in place, ensuring everything stays aligned during high-speed flight.

Even under the vibrations and forces that drones experience in the air, the E-ring keeps the motor running smoothly and reliably. This small but essential part maintains performance and stability.

Connect With Our Experts About Your Aerospace Project

No matter where you are in your build, our team can get you the right parts. Our reputation is your assurance.