Solving Thermal Expansion Challenges with Wave Springs in Automotive & Industrial Applications

Thermal expansion is a common challenge in applications exposed to high temperatures or in systems using temperature-sensitive materials, such as automotive exhaust systems, aerospace components, heavy-duty off-highway or industrial machinery, and fluid or valve assemblies in construction and energy equipment.

As external components expand during operation, internal parts like retaining rings, wave springs, and other preload elements can loosen, potentially causing unwanted movement, vibration, and noise. Design engineers address these issues by pre-loading components with wave springs, which are engineered to compensate for thermal expansion and keep assemblies secure throughout varying temperature cycles.

Not all wave springs can handle the wide range of axial endplay caused by thermal expansion. Selecting the right wave spring requires careful consideration of material, configuration, and work height to ensure consistent performance and reliability. Proper selection is critical when designing assemblies that must maintain precise preload under varying temperature conditions.

Case Study: Preloading an Automotive Sensor with Single-Turn Wave Spring

A client in the automotive industry faced a challenge with a temperature and pressure sensor used in an exhaust gas system. The sensor needed to remain precisely seated in its metal housing, but the exhaust system experienced frequent heating and cooling cycles, causing uneven expansion of the housing and surrounding parts. This variation in expansion risked loosening the sensor, which could result in vibration, noise, inaccurate sensor readings, or even sensor failure over time.

The client turned to Rotor Clip for a solution. The original design relied on a conventional disc spring to preload the sensor and maintain a tight fit, but testing showed that the disc spring could not provide sufficient work height to compensate for the full range of thermal expansion. As a result, the sensor remained at risk of shifting within the housing, potentially compromising both its performance and reliability.

Our Solution

Rotor Clip engineers solved this challenge by replacing the disc spring with our single-turn wave spring, made from A286 stainless steel (DIN Material No. 1.4980). The wave spring addressed three critical application challenges identified during testing:

-

Compensation for thermal expansion:

The wave spring provides sufficient axial travel to accommodate the maximum expansion within the exhaust system, keeping the sensor securely seated under all operating conditions.

-

Durability at high temperatures:

A286 stainless steel resists creep under elevated temperatures, extending the life of both the wave spring and the sensor assembly—critical for exhaust systems operating under harsh thermal conditions.

-

Simplified assembly:

Unlike disc springs, the wave spring naturally “clings” to the housing, eliminating a secondary assembly step, reducing assembly time, and minimizing the risk of errors.

By addressing these challenges simultaneously, the wave spring delivers a reliable, long-lasting solution for maintaining preload in applications affected by thermal expansion.

Why Wave Springs Are a Versatile Solution

Wave springs offer a high degree of design flexibility that traditional springs cannot match. Rotor Clip engineers leverage this versatility to develop solutions that optimize performance, reduce space, and improve reliability in demanding applications. Their engineered profiles deliver precise preload, minimize axial height, reduce material usage, and accommodate a wide range of loads and deflections. Compared to conventional disc or coil springs, wave springs provide consistent force and simplify complex assemblies, making them an ideal choice for engineers seeking efficiency and precision.

Available in multiple materials, configurations, and sizes, wave springs are ideal for applications such as automotive sensors, aerospace components, industrial machinery, fluid control systems, and valve assemblies. Their compact design, predictable performance, and ability to replace multiple stacked disc springs make them a reliable choice for engineers seeking efficiency, durability, and precision.

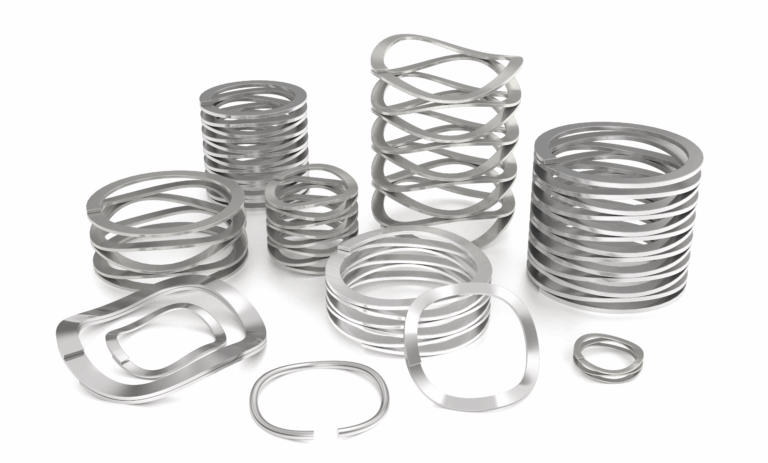

Rotor Clip Wave Spring Products

Rotor Clip offers a comprehensive range of high-performance wave springs to meet a variety of engineering needs:

-

Single-Turn Wave Springs

Ideal for preload or tolerance takeup in tight spaces; they deliver precise preload with minimal axial height.

-

Multi-Turn Wave Springs

Compact and robust replacement for coil springs or stacks of disc springs; they can save up to 50% of axial space compared to traditional springs while handling a wide range of loads and deflections.

-

Round-Wire Wave Springs

Designed for highload, low deflection, static or low cycle applications; they provide a cost-effective alternative to disc springs where space or profile is limited.

-

Nested Wave Springs

Layered coils provide significantly increased load capacity in minimal axial and radial space; best suited for high static load applications where space is constrained.

-

Linear Wave Springs

Ideal when preload or tolerance takeup is needed along a straight groove or channel; these springs are customizable in length and geometry to fit unusual or constrained assemblies.

Unsure which wave spring is best for your application? Our engineers have the expertise to guide you and select the ideal solution, helping you choose the right material, size, style, and configuration. Contact us now to get started.